FILTRATION AND CENTRIFUGATION

FILTRATION AND CENTRIFUGATION

Filtration

It may be define as a process of separation of solids from a fluid by passing the same through a porous medium that retains the solids but allows the fluid to pass through

Removal of solid particles from a fluid by passing the fluid through a filtering medium, or septum

Clarification

When solid are present in very low concentration, i.e., not exceeding 1.0% w/v, the process of its separation from liquid is called clarification

Mechanism of filtration

The mechanism whereby particles are retained by a filter is significant only in initial stages of filtration. Straining

- Similar to sieving, i.e., particles of larger size can’t pass through smaller pore size of filter medium Impingement

- Solids having the momentum move along the path of streaming flow and strike (impinge) the filter medium. Thus the solids are retained on the filter medium

Entanglement

- Particles become entwined (entangled) in the masses of fibres (of cloths with fine hairy surface or porous felt) due to smaller size of particles than the pore size. Thus solids are retained within filter medium

Attractive forces

- Solids are retained on the filter medium as a result of attractive force between particles and filter medium, as in case of electrostatic filtration

Difference between surface and depth filtration

Surface filtration

- The size of particles retained is slightly higher than the mean pore size of medium

- Mechanical strength of filter medium is less, unless it is made of stainless steel

- It has low capacity

- The size of particles retained is more predictable

- Equipment is expensive because ancillary equipment such as edge clamps is required. Ex. Cellulose membrane filter Depth filtration

- The size of particles retained is much smaller than the mean pore size of medium

- Mechanical strength of filter medium is high.

- It has high capacity

- The size of particles retained is less predictable

- Equipment is cheaper because ancillary equipment is not required. Ex. Ceramic filters and sintered filters

Types of filtration

Surface/ screen filtration

It is a screening action by which pores or holes of medium prevent the passage of solids Mechanism involved: straining and impingement

For this, plates with holes or woven sieves are used

Efficacy is defined in terms of mean or maximum pore size.

Depth filtration

In this slurry penetrates to a point where the diameter of solid particles is greater than that of the tortuous void or channel

Mechanism: Entanglement

The solids are retained with a gradient density structure by physical restriction or by adsorption properties of medium

Applications of filtration

- Production of sterile products:

HEPA filters or laminar air bench

Membrane filters

- Production of bulk drugs

- Production of liquid dosage

- Effluents and waste water treatment

Theories of filtration

- The flow of liquid through a filter follows the basic rules that govern the flow of any liquid through the medium offering resistance

- The rate of flow may be expressed as

Rate = driving force / resistance

- The rate of filtration may be expressed as volume (litres) per unit time (dv/dt)

Driving force = pressure upstream – pressure downstream

- Resistance is not constant

- It increases with an increase in the deposition of solids on the filter medium

- Therefore filtration is not a steady state

- The rate of flow will be greatest at the beginning of filtration process, since the resistance is minimum.

- After forming of filter cake, its surface acts as filter medium and solids continuously deposit adding to thickness of the cake.

Resistance to flow is related to several factors as shown in the figure

Resistance to movement= {pressure upstream- pressure downstream} / length of capillaries

Poiseullie’s Equation

- Poiseullie considered that filtration is similar to the streamline flow of liquid under pressure through capillaries

- Poiseullie’s equation is

![]()

Where, V = rate of flow, m3/s (l/s)

ΔP= Pressure difference across the filter, Pa

r = radius of capillary in the filter bed, m

L = thickness of filter cake (capillary length), m

η = viscosity of filtrate, Pa.s

- If the cake is composed of bulky mass of particles and the liquid flows through the interstice, then flow of liquids through these may be expressed by this equation.

Darcy’s Equation

- Poiseullie’s law assumes that the capillaries found in the filter are highly irregular and non- uniform

- Therefore, if the length of capillary is taken as the thickness of bed, a correction factor for radius is applied so that the rate is closely approximated and simplified

- The factors influencing the rate of filtration has been incorporated into an equation by Darcy, which is:

![]()

Where, K = permeability coefficient of cake, m2

A = surface area of porous bed (filter medium), m2

Other terms are same as previous equation

- K depends on characteristics of cake, such as porosity, specific surface area and compressibility.

- Permeability may be defined quantitatively as the flow rate of a liquid of unit viscosity across a unit area of cake having unit thickness under a pressure gradient of unity

- This equation is valid for liquids flowing through sand, glass beds and various porous media

- This model is applied to filter beds or cakes and other types of depth filter

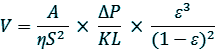

- This equation is further modified by including characteristics of K by Kozeny-Carman

Kozeny-Carman (K-C) equation

- Kozeny-Carman equation is widely used for filtration.

Where, V = porosity of cake (bed)

S = specific surface area of particles comprising the cake m2 / m3

K = Kozeny constant (usually taken as 5)

Other terms are same as previous equations

Limitations

It does not consider the fact that depth of granular bed is lesser than the actual path traversed by the fluid. The actual path is not same throughout the bed, but it is sinuous or tortuous.

Factors Influencing Filtration

1. Surface area of filter medium

Rate of filtration

a) Inversely proportional to specific surface of filter bed (According to K-C equation)

b) Directly proportional to surface area of filter medium (According to Darcy’s equation)

Rate can be increased either using large filter or connecting a number of small units in parallel Filter press works on principle of connecting units in parallel.

2. Pressure drop across the filter medium

- According to K-C equation the rate of filtration is proportional to the overall pressure drop across both the filter medium and filter cake.

- The pressure drop can be achieved in a number of ways:

Gravity: A pressure difference could be obtained by maintaining a head of slurry above the filter medium. The pressure developed will depend on the density of the slurry

Vaccume: The pressure below the filter medium may be reduced below atmospheric pressure by connecting the filtrate receiver to a vacuum pump and creating a pressure difference across the filter

Pressure: The simplest method being to pump the slurry into the filter under pressure

Centrifugal force: The gravitational force could be replaced by centrifugal force in particle separation

3. Viscosity of filtrate

- According to K-C equation rate of filtration is inversely proportional to the viscosity of the fluid

- Reason behind this is an increase in the viscosity of the filtrate will increase the resistance of flow

- This problem can be overcome by two methods:

a) The rate of filtration may be increased by raising the temperature of the liquid, which lowers its viscosity. However, it is not practicable if thermolabile materials are involved or if the filtrate is volatile

b) Dilution is another alternative but the rate must be doubled

4. Filter Media

- The surface upon which solids are deposited in a filter is called the “Filter medium”

- Properties of ideal filter medium:

- It should-

– Be capable of delivering a clear filtrate at a suitable production rate

– Have sufficient mechanical strength

– Be inert

– Retain the solids without plugging at the start of filtration

– Not absorb dissolve material

– Sterile filtration imposes a special requirement since the pore size must not exceed the dimension of bacteria or spores

Filter Aids

- The objective of filter aid is to prevent the medium from becoming blocked and to form an open, porous cake, hence, reducing the resistance to flow of the filtrate

- Filter aid forms a surface deposit which screens out the solids and also prevents the plugging of supporting filter medium

Characteristics of filter aids

- Chemically inert and free from impurities

- Low specific gravity, so remain suspended in liquids

- Porous rather than dense, so that pervious cake can be formed

- Recoverable

Disadvantages

- Remove the coloured substances by absorbing them

- Sometimes active principles such as alkaloids are absorbed on filter aid

- Rarely, filters are source of contamination such as soluble iron salts, which can provoke degradation of sensitive ingredient

Pretreatment of Filtration

Adsorption on Filter Aids

* Why filter-aid filtration?

Two major problems can be reduced:

(1) High compressibility of the accumulated biomass

(2) Penetration of small particles into the filter medium

Lengthen the filtration cycle; improve the quality of the filtered liquor

* How does the filter-aid help?

(1) Give porosity to the filter cake

Solids to be filtered Porosity

Hard spheres of the same size =0.45

General cases 0.2-0.3

Compressible solids =0

Diatomaceous silica =0.9

(2) Create a very large surface to trap the gelatinous precipitate.

Allow much more filtrate to be obtained before eventually clogging up

Handling of filter aids

Filter aids may be used in either or both two ways:

1) Pre- coating technique: by forming a pre-coat over the filter medium by filtering a suspension of the filter aid.

2) Body- mix technique: A small proportion of the filter aid (0.1-0.5 %) is added to the slurry to be filtered. This slurry is recirculated through the filter until a clear filtrate is obtained, filtration then proceeds to completion.

Different flow rates can be achieved depending on grade of aid –

- Low flow rate: fine grade filter aids- mainly used for clarity

- Fast flow rate: coarse grade filter aids- acceptable filtrate

Examples of filter aids • Diatomite (Keiselgur), obtained from natural siliceous deposits.

- Perlite, it is an aluminium silicate. Cellulose, Asbestos, charcoal, talc, bentonite, fullers earth

Classification of filtration equipment’s

- Based on application of external force:

Laboratory scale filtration

Filter paper and funnel

Buchner funnel and filter paper

Sintered glass filter

Seitz filter

Membrane filter

Filter leaf

Principle

- It is an apparatus consisting of a longitudinal drainage screen covered with a filter cloth

- The mechanism is surface filtration and acts as sieve or strainer

- Vacuum or pressure can be applied to increase the rate of filtration

Construction

- The leaf filter is consisting of a frame enclosing a drainage screen or grooved plate

- The frame may be any shape circular, square or rectangular

- The whole unite being covered with filter cloth

- The outlet for the filtrate connects to the inside of the frame through suction

Working and uses

Use

Use for the filtration of slurry which do not contain high solid content, about 5%, i.e. dilute suspensions

Advantages

- Simplest form of filter used for batch process

- A number of units can be connected in parallel to increase the surface area of filtration

- Pressure difference can be obtained either with vacuum or using pressure up to the order of 800 kilopascals • Labour costs for operating the filter leaf are fairly moderate

- The efficiency of washing is high

- The slurry can be filtered from any vessel

- The cake can be washed simply by immersing the filter in a vessel of Water

Candle Filter

The Candle Filters are, as all pressure filters, operating on a batch cycle and may be seen in process lines handling titanium dioxide, flue gas, brine clarification, red mud, china clay, fine chemicals and many other applications that require efficient low moisture cake filtration or high degree of polishing

The Candle Filter consists of three major components:

- The vessel

- The filtering elements

- The cake discharge mechanism

The Vessel

There are two types of vessel configuration:

- Vessels with conical bottom for cake filtration and polishing

- Vessels with dished bottom for slurry thickening

The Cake Discharge Mechanism

There are two methods to discharge the cake at the end of the cycle:

- Snap blow

- Vibrating mechanism

Cakes that discharge readily a snap blow from the backside of the medium is sufficient to release the cake but cakes that are difficult to discharge require a mechanism that assists release by vibrating the entire pack of candles

In this instance it is good practice to incorporate special headers with high impact sprays in the upper part of the vessel to clean the candles and dislodge entrained particles

Advantages

- Excellent cake discharge

- Adapts readily to slurry thickening

- Minimum floor space

- Mechanically simple since there are no complex sealing glands or bearings

Disadvantages

- High headroom is required for dismantling the filtering elements

- The emptying of the vessel in between cake filtration, washing and drying requires close monitoring of the pressure inside the vessel to ensure that the cake holds on to the candles

Metafilter

Principle

- Mechanism is surface filtration

- In this, metal rings contain semicircular projections, which are arranged as a nest to form channels on the edges • This channel offers resistance (strainer) to the flow of solids (coarse particles)

- The clear liquid is collected into receiver from the top

Construction

- Metafilter consists of a series of metal rings

- These are threaded so that a channel is formed on the edges

- It contains a grooved drainage column on which a series of metal rings are packed

- These rings are usually made up of stainless steel and have dimensions of about 15.0 mm internal diameter and 22.0 mm external diameter

- Each metal ring has a number of semicircular projections (0.8 mm in thickness) on one side of surface

- The projections are arranged as a nest to form channels on the edges

- These rings are tightened on the drainage column with a nut

- Metafilters are also known as edge filters

Working

For separation of fine particles, a bed of suitable materials such kieselguhr is first built up.

The pack of rings serves essentially as a base on which the true filter medium is supported.

Advantages

- Can be used under high pressures, without any danger of bursting the filter medium

- Running cost are low, as separate filter medium is not used

- Can be constructed from a material that can provide excellent resistance to corrosion and avoid contamination of sensitive products

- It is extremely versatile filter because fine as well as large both type of particles can be separated

- Removal of cake can be carried out by simply back- flushing with water

- Change over from one batch to another or one product to another is easy

- Sterile products can be handled

Uses

Meta filters can be used for –

- Clarification of syrups

- Filtration of injection solutions

- Clarification of insulin liquors

- Filtration of viscous liquids can be achieved by applying pressure

Plate and frame filter press

Principle

- Mechanism is surface filtration

- The slurry enters the frame by pressure and flows through filter medium

- The filtrate is collected on the plates and send to outlet

- A number of frames and plates are used so that surface area increases and consequently large volumes of slurry can be processed simultaneously with or without washing

Construction

- The Filter press is made of two types of units, plate and frames.

- Usually made of aluminium alloy.

- Sometimes, these are also lacquered for protection against corrosive chemicals and made suitable for steam sterilization.

Frame

It contains an open space inside wherein the slurry reservoir is maintained for filtration and an inlet to receive the slurry. It is indicated by two dots in description.

- Frames of different thickness are available.

- It is selected based on the thickness of cake formed during filtration.

- Optimum thickness of frame should be chosen.

Plate

The plate has a studded or grooved surface to support the filter cloth and an outlet.

It is indicated by one dot in description.

- Plate supports the filter medium, receiving the filtrate and outlet

- The filter medium usually cloth is interposed between plate and frame

- Plate, filter medium, frame, filter medium and plate are arranged in sequence and clamed to a supporting structure

- It is normally described by dots as 1.2.1.2.1 so on

- A number of plates and frames are employed so that the filtration area is as large as necessary.

- Number of filtration units are operated in parallel

- Channels for slurry inlet and filtrate outlet can be arranged by fitting eyes to the plates and frames, these join together to form a channel

- In some types only one inlet channel is formed, while each plate is having individual outlets controlled by valves

Assembly of plate and frame filter

Working

- Working can be divided into two steps

- Filtration operation

- Washing of cake (if desirable)

- Filtration operation

Advantages

- Provide large filtration area in relatively small floor space. The capacity being variable according to thickness of frames and number used

- Sturdy construction permits the use of considerable pressure difference. (2000 Kilopascals normally used) • Efficient washing of cake is possible

- Operation and maintenance is easy

- It produce dry cake in form of slab

Disadvantages

- It is a batch filter, so it is a time consuming

- The filter press is an expensive filter; the emptying time, the labour involved, and the wear and tear on the cloths resulting in high costs

- Operation is critical, as the frames should be full, otherwise washing is inefficient and the cake is on the cloths resulting in high costs difficult to remove

- The filter press is used for slurries containing less about 5 % solids

- In view of the high labour costs, it is most suitable for expensive materials e.g. the removal of precipitated proteins from insulin liquors.

Centrifugation

Centrifugation is a Unit operation employed for separating the constituents present in a dispersion with the aid of centrifugal force

- Centrifuge is device for separating particles from a solution according to their size, shape, density, viscosity of the medium

- Centrifugal force provides the driving force for the separation

- It replaces gravitational forces operating during the sedimentation

- The equipment used for the separation are known as centrifuges

Applications of Centrifugation

Production of bulk drug

Centrifugation technique is used to separate crystalline drugs such as aspirin from the mother liquor Free flowing products results due to the removal of traces of mother liquor and avoidance of effervescence Production of biological products

Most of the proteinaceous drugs and macromolecules are present as colloidal dispersion in water

By normal method, it is difficult to produce them in large scale. Centrifugation is employed for separating the blood cells from blood

Biopharmaceutical analysis of drugs

Drugs present in the blood tissue fluids and urine are normally present in the form of colloidal dispersion

Centrifugation is used for separating the drugs

This method is essential for the evaluation of pharmacokinetic parameters and bioequivalence studies

Evaluation of suspension and emulsion

Centrifugation method is used as a rapid empirical test parameter for the evaluation of suspension and emulsion. Normally, creaming is slow process in emulsions.

This process can be hastened by inducing stress condition (using a Centrifuge)

A stable emulsion should not show any signs of separation even after centrifuging at 2000-3000 revolution per minute at room temperature

Determination of molecular weight of colloids

Determination of molecular weight of a polymer is not possible by usual methods.

Ultra-centrifugation method are used for determination of molecular weight of serum albumin, insulin, methyl cellulose

For example, insulin is monodisperse protein composed of two polypeptide chains, whereas gelatin is found to be polydisperse protein with fraction of moleculer weight 10,000 to 1, 00,000.

Principle of centrifugation

If particles size in the dispersions is 5 micro meter or less, they undergo Brownian motion, hence they do not Sediment under gravity

Therefore a stronger force, centrifugal force is applied in order to separate

Centrifugal Effect or relative Centrifugal Force (RCF)

- The centrifugal operation is described by equations including the gravitational constant. The derivation is as follows.

- Consider a body of mass m Kg rotating in a circular path radius r metres at a velocity of v metres per minute. The force acting on the body in a radial direction is given by:

- Force acting in radial direction,

F=mv2/r …….. (1)

- Where F=centrifugal force, N

- The same body is experiencing gravitational force (newton). It can be expressed as:

Gravitation force, G=mg …..(2)

Where g= acceleration due to gravity, m/s2

The centrifugal effect is expressed as a ratio of centrifugal force to gravitational force. In other words centrifugal force, which is a number of time greater than the gravitation force

Separation power of centrifuge is expressed as a ratio of the centrifugal force to the gravitational acceleration. This ratio may have a value as high as 10 4

- The centrifugal effect can be expressed as:

Centrifuge, C= force acting in radial direction/gravitational force

C= F/G

- But v = mπrn, Where n= speed of rotation (revelations per second of centrifuge). Substituting this in equation (3 yields)

C= (2πrn)2/ gr = 4π2 r2 n2/gr = 4π2 r2 n2/g ….(4)

- Since 2r =d, where d- diameter of the rotation. Substituting the value in equation (4) gives:

C= 2π2dn2/ g ……….. (5)

- The gravitational constant has a value of 9.807 m/s2, so that equation (5) can be simplified as:

Centrifugal effect =2.013n2 d ………….(6)

- In the equation (6), n is expressed in s-1 and d is in metres

The measurement of d is made from the free surface of liquid (or from the tip of the tube) to the centre of a centrifuge and should be mentioned while reporting the centrifugal effect

From equation (5) and (6), it can be inferred that

Centrifugal effect α diameter

Centrifugal effect α (speed of rotation)2

Classification of centrifuges

There are two main types of centrifuge used to achieve separation on an industrial scale,

(1) Filtration centrifuge

Those using perforated baskets, which perform a filtration-type operation (work like a spin-dryer)

(2) Sedimentation centrifuge

Those with a solid walled vessel, where particles sediment towards the wall under the influence of the centrifugal

Classification (Based on scale of usage)

Laboratory scale

Horizontal spinning type

Angle centrifuge 945 to 50 angels)

High speed centrifuge (10,000 rpm)

Ultra centrifuge (85,000 rpm)

Commercial scale

Batch type: Short basket centrifuge

Semi continuous scale: Short-cycle batch centrifuge

Continuous centrifuge: Super centrifuge

Perforated Basket Centrifuge

Principle

- It is a filtration centrifuge. The separation is through a perforated wall based on the difference in the densities of solid and liquid phases

- The bowl contains a perforated side wall

- The liquid phase passes through the perforated wall, while solid phase is retained in the bowl

- The solid is removed after cutting the sediment by a blade after stopping the centrifuge

Construction

It consists of a stainless steel perforated basket (typically 1-2 m in diameter) lined with a filter cloth The basket rotates at a speed which is typically < 25 s-1, higher speeds tending to stress the basket excessively The product enters centrally and is thrown outwards by centrifugal force and held against the filter cloth The filtrate is forced through the cloth and removed via the liquid outlet; the solid material is retained on the cloth The cake can be washed if required by spraying water into the centrifuge

Working

- The material is kept on a basket when the basket is stationary

- The amount of material should be optimum, otherwise, during Centrifugation it puts a great strain on the basket. The loading of material done to give even distribution

- Power is applied to rotate the basket and maximum speed must be attained quickly

- The basket runs at 1000 revolutions per minutes

- The power require for running is small compared to the power require for starting and bringing it to the full speed

- During Centrifugation, the liquid passes through the perforated wall, while the solid phase retains in the basket • The liquid leaves the basket and is collected at the outlet

- The cake is then spun to dry as much as possible

- Sometimes higher speeds are used so that the cake will be completely dried

- After a definite period of time, the power is turned off. By applying a brake the Centrifuge is stopped

- The basket is brought to rest

- The solid cake is cut using a blade and then unloaded manually

Uses

- Perforated basket Centrifuge is extensively used for separating crystalline drugs (such as aspirin) from the mother liquor is removed completely

- It is also used for removing unwanted solids from a liquid. For example, precipitated proteins are removed from insulin

- Sugar crystals are separated using perforated basket centrifuge

Advantages

- The Centrifuge is very compact and it occupies very little floor space

- It can handle slurries with a high proportion of solid and even those having paste like consistency

- The final product has a very low moisture content

- In this method, the dissolved solids are separated from the cake

- The process is rapid

Disadvantages

- The entire cycle is complicated resulting in considerable labour costs

- It is a batch process

- If the machine is adapted for prolonged operation, there is considerable were and tear of the equipment. On prolonged operation, the solids may from hard cake, due to the centrifugal force, which is difficult to remove simultaneously.

Tubular-bowl centrifuges (centrifugal sedimenters)

Used to separate solids and liquids when the solid content is low. These consist of a cylindrical ‘bowl’ Around 100 mm in diameter and 1 m long, which rotates at 300-1000 s-1

The product enters at the bottom and centrifugal force causes solids to be deposited on the wall as it passes up the bowl The liquid overflows from the top

This type of centrifuge can also be used to separate immiscible liquids

Rate of sediment can be control by controlling the inlet rate

The uses of centrifugal sedimenters include liquid/liquid separation

E.g. During antibiotic manufacture and purification of fish oils, the removal of very small particles, the removal of solids that are Compressible and which easily block the filter medium

The separation of blood plasma from whole blood (need C =3000)

The separation of different particle size fractions, and examining the stability of emulsions

Principle

- Super centrifuge is a sedimentation centrifuge

- The separation is based on the difference in the densities between two immiscible liquids

- Centrifugation is done in the bowl of small centrifuge

- During centrifugation, the heavier liquid is thrown against the wall, while the lighter liquid remains as an inner layer

- The two layers are simultaneously separated using modified weirs

Construction

- It consists of a long hallow cylindrical bowl of small diameter

- It is suspended from a flexible spindle at the top and guided at the bottom by loose-fit bushing • It can be rotated on its longitudinal axis

- Provision is made at the bottom for the feed inlet using pressure system

- The liquid outlets are provided at different heights at the top of the bowl, and modified weirs, are attached

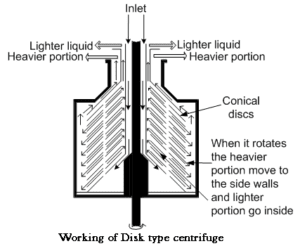

Conical Disc Centrifuge / De laval Clarifier

Conical Disc Centrifuge

As it is a clarified, solids or immiscible liquids are present in low concentration in the feed complete clarification of the feed is possible by centrifugal means

Principle

- It is a sedimentation centrifuge

- The separation is based on the difference in the densities between the phases under the influence of centrifugal force

- In this, a number of cone shaped plates are attached to a central shaft (which has the provision for feed) at different elevations

- During centrifugation, the dense solids are thrown outwards to the underside of the cone shaped casing, while the lighter clarified liquid passes over the bowl and recovered from the top of the cone

Construction

- The construction of a conical disc centrifuge is shown in figure

- It construction of a shallow form of bowl contacting a series of conical disc are made up of a thin sheet of metal or plastic separated by narrow spaces

- Matching hole in the disc (above half way between the axis and the wall of the bowl) from channel through which the liquid passes

- A concentric tube is placed surrounding the central drive shaft

Working

- Centrifuge is allowed to rotate.

- Low speed and short time of centrifugation is sufficient to give high degree of clarification

- The feed is introduced through the concentric tube surrounding the shafts

- The feed flow down and enters in to the space between the discs (show by the narrows)

- During centrifugation, the liquid flow in to the channel (holes at the centre of disc) and upward past the discs

- These substances move along the surfaces of the discs to the limits of the inner and outer layers • The solids and heavy liquids are thrown outward and move underside of the discs

- Then the solids deposit at the bottom of the cone, which is removed intermittently

- The lighter liquid moves to the upper side of the discs

- The liquid raises to the top and escapes from the outlet

Uses

- Two immiscible liquids can be easily separated by a continuous process after liquid/liquid extraction as in case of manufacture of antibiotics

- Suspensions containing low concentration of solids can be separated quickly. Solids that are gelatinous are slimy can be separated by disc cone centrifuge. Such substances may plug the filter in the other methods

- Starch is collected after washing and purification stages

- In the manufacture of insulin, the liquor is clarified to remove the precipitated proteins

- Concentration of one fluid phase is possible as in the separation of cream from milk, concentration of rubber latex, removing solids from lubricating oils, inks and beverages

Advantages

- Conical disk centrifuges are compact occupying a very small space

- The separating efficiency is very high, so that the particle are deposited very rapidly. It is suitable, if the sediment is a fluid deposit or sludge

- By controlling the speed of rotation and rate of flow, particle are separated intotwo size fractions

Disadvantages

- The construction of a conical disc centrifuge is complicated

- Its capacity is limited

- It is not suitable if the sediment of solid forms a hard cake

Summary

- Filtration is the removal of solid particles from a fluid by passing the fluid through a filtering medium, or septum

- Straining, impingement, entanglement and attractive forces are the mechanisms of filtration

- Surface filtration is a screening action by which pores or holes of medium prevent the passage of solids and depth filtration involves penetration of slurry to a point where the diameter of solid particles is greater than that of the tortuous void or channel

- Poiseullie’s equation, Darcy’s equation and Kozeny-Carman equations are the laws associated with filtration

- The various properties influencing filtration are properties of solid, liquids, temperature, surface area of the filter medium, viscosity of filtrate, filter media and pressure drop across the filter medium

- Filter aids are used to prevent the medium from becoming blocked by reducing the resistance to flow of the filtrate

- Two methods of handling filter aid are pre coating and body mix techniques

- Filtration equipments are categorized based on nature of external force ,nature of filtration and lab scale operation

- Filter leaf consists of a frame enclosing a drainage screen or grooved plate used for the filtration of slurry which do not contain high solid content

- Candle Filter is a batch cycle pressure filter, used for handling titanium dioxide, flue gas, brine clarification, china clay, fine chemicals requiring low moisture high degree of polishing

- Meta filter works by surface filtration used for clarification of syrups, insulin liquors and filtration of injection solutions • Filter press operates on the basis of surface filtration comprising of plate and frame

- Filter press provides a large filtration area in relatively small floor space with easy operation andmaintenance

- Filter press is an expensive filter as the emptying time, the labour involved, and the wear and tear onthe cloths results in high costs

- Centrifugation is employed for separating the constituents present in a dispersion and centrifuge isthe device used for separating particles from a solution according to there size, shape, density, viscosity of the medium

- Pharmaceutical applications of centrifugation are production of bulk drug, biological products, biopharmaceutical analysis of drugs and determination of molecular weight of colloids

- Centrifugal force is required to bring out the separation by centrifugation

- Centrifugal effect is the ratio of centrifugal force to gravitational force

- Centrifuge based on filtration and sedimentation used for industrial application are perforated basket, tubular bowl and super centrifuge

- Perforated basket centrifuge separates the sample through a perforated wall based on the difference in the densities mainly for crystalline drugs from mother liquor and precipitated proteins from insulin

- Tubular bowl centrifuge or super centrifuge is used when the solid content is low

- Conical disc centrifuge or sedimentation centrifuge works on the difference in the densities between the phases under the influence of centrifugal force

For Detailed PDF Notes Click on Download Button