Manometers

Manometers

Manometers are the devices used for measuring the pressure difference.

Manometers are widely used to measure pressure, a crucial parameter in fields such as engineering, medicine, and research. Understanding how these devices work is fundamental for professionals and enthusiasts alike.

Different type of manometers are there they are

· Simple manometer

· Differential manometer

· Inclined manometer

Types of Manometers

Simple manometer

• This manometer is the most commonly used one

• It consists of a glass U shaped tube filled with a liquid A- of density ρA kg /meter cube and above A the arms are filled with liquid B of density ρB

• The liquid A and B are immiscible and the interference can be seen clearly

• If two different pressures are applied on the two arms the meniscus of the one liquid will be higher than the other

• Let pressure at point 1 will be P1 Pascal’s and point 5 will be P2 Pascal’s

• The pressure at point 2 can be written as = P1+ (m + R ) ρ B g

(m + R ) = distance from 3 to 5

Differential manometers

• These manometers are suitable for measurement of small pressure differences

• It is also known as two – Fluid U- tube manometer

• It contains two immiscible liquids A and B having nearly same densities

• The U tube contains of enlarged chambers on both limbs

• Using the principle of simple manometer the pressure differences can be written as

∆P =P1 –P2 =R (ρc – ρA) g

Hence smaller the difference between ρc and ρA larger will be R

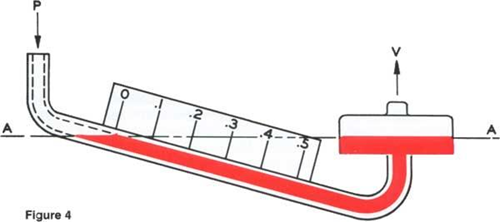

Inclined tube manometers

Many applications require accurate measurement of low pressure such as drafts and very low differentials, primarily in air and gas installations.

In these applications the manometer is arranged with the indicating tube inclined, as in Figure, therefore providing an expanded scale.

This enables the measurement of small pressure changes with increased accuracy.

P1 –P2 = g R (ρ A – ρ B) sin α

Measurement of rate of flow of fluids

Whenever fluid are used in a process it is necessary to measure

The rate at which the fluid is flowing through the pipe

Methods of measurement are

1. Direct weighing or measuring

2. Hydrodynamic methods

· Orifice meter

· Venturi meter

· Pitot meter

· Rotameter

3. Direct displacement meter

Applications of Manometers

Manometers have diverse applications, including industrial and medical settings. They play a crucial role in ensuring safety and accuracy in many processes.

Industrial Applications

In industrial settings, manometers are used for monitoring and controlling pressure in processes like chemical manufacturing, HVAC systems, and hydraulic systems.

Medical Applications

Manometers are indispensable tools in medicine, employed for measuring blood pressure, monitoring respiratory systems, and ensuring patient safety.

Advantages and Disadvantages of Manometers

Understanding the pros and cons of manometers is essential for selecting the right device for your specific needs.

Pros of Manometers

- Precision: Manometers provide highly accurate pressure measurements.

- Versatility: They can be used in various industries and applications.

- Reliability: Manometers are durable and require minimal maintenance.

Cons of Manometers

- Fluid Selection: The choice of the right fluid is critical for accurate measurements.

- Sensitivity: Manometers can be affected by external factors, such as temperature changes.

- Cost: High-quality manometers can be expensive.

Maintenance and Calibration

Proper maintenance and periodic calibration are essential to ensure the accuracy and longevity of manometers. Regular checks and adjustments are crucial for reliable readings.

Conclusion

Manometers are vital tools for precise pressure measurement. Their applications span across diverse fields, and understanding their principles and maintenance is key to their effective use. Whether you are in industry or healthcare, manometers play a crucial role in ensuring safety and efficiency.

FAQs

What is the purpose of a manometer?

A manometer is used to measure and monitor pressure, ensuring the safety and efficiency of various processes in industries and medical applications.

How to calibrate a manometer?

Manometers should be calibrated regularly by comparing their readings to a reference standard. Adjustments should be made if necessary.

Are manometers suitable for high-pressure measurements?

Yes, manometers can be designed to measure high pressures, but the choice of the right manometer type and fluid is critical.

Can a manometer measure gas pressures?

Manometers are versatile and can measure both liquid and gas pressures, depending on their design and calibration.

Where can I buy a manometer?

Manometers are available from various manufacturers, suppliers, and online retailers. You can find them in specialized instrument stores and websites.

Also, Visit:

B. Pharma Notes | B. Pharma Notes | Study material Bachelor of Pharmacy pdf