Silverson

mixer -Emulsifier

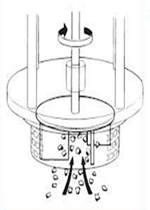

Principle

• It produces intense shearing forces and turbulence by use

of high speed rotors

• Circulation of material takes place through the head by

the suction produced in the inlet at the bottom of the head

• Circulation of the material ensures rapid breakdown of the

dispersed liquid into smaller globules

• It consists of long supporting columns and a central

portion. Central portion consists of a shaft which is connected to motor at one

end and other to the head

• Head carries turbine blades

• Blades are surrounded by a mesh, which is further enclosed

by a cover having openings

Construction

It consists of a emulsifier head which is covered with the

fine meshed stainless steel sieve

The emulsifier head consist of a number of blades which

rotates at high speed in order to produce a powerful shearing action

The blades are rotated by using the electric motor fitted at

the top.

Working

•The emulsifier head is placed in the vessel containing

immiscible liquids, in such a way that it should get dipped into it

•When the motor is started, the liquids are sucked through

the fine holed and the oil is reduced into the globules due to the the rotation

of the blades

•The precision machined Silverson work head generates

exceptionally high shear rates in a four stage mixing/homogenizing process:

Stage 1

The high-speed rotation of the rotor blades within the

precision machined mixing work head exerts a powerful suction, drawing liquid

and solid materials upwards from the bottom of the vessel and into the center

of the workhead

Stage 2

Centrifugal force then drives the materials to the periphery

of the workhead and subjects them to mechanical shear

Stage 3

This is followed by intense hydraulic shear and circulated

back into the mix as the product is forced through the stator screen at high

velocity.

Fresh material is continually drawn into the workhead,

progressively reducing globule or particle size and quickly resulting in a

homogeneous, uniform product

Stage 4

The materials expelled from the head are projected radially at

high speed towards the sides of the mixing vessel. At the same time, fresh

material is continually drawn into the workhead maintaining the mixing cycle

Uses

• Used for the preparation of emulsions and creams of fine

particle size

Advantages

• Silver son mixer is available in different sizes to handle

the liquids ranging from a few milli liters to several thousand liters

• Can be used for batch operations as well as for continuous

operations by incorporating into a pipeline, through which the immiscible liquids

flow

Disadvantages

• Occasionally, there is a chance of clogging of pores of

the mesh