Microencapsulation

Learning Objectives

At the end of the session, student will be able to:

• Identify mutiparticulate drug delivery systems

• Differentiate between microparticles and macroparticles

• Differentiate between microspheres and microcapsules

• Enlist the methods for microencapsulation

• Describe air suspension technique for microencapsulation

• Discuss the steps in microencapsulation by conservation phase separation technique

• Analyze the differences between spray drying and spray congealing procedures

• Explain microencapsulation by pan coating method

• Discuss solvent evaporation technique for microencapsulation

• Outline interfacial polymerization technique

• Classify coating materials used in microencapsulation with examples

• Outline the applications of microencapsulation techniques in pharmaceutical and other fields

Introduction to multiparticulate drug delivery system

✓ The active substance is present in a number of small independent units

✓ To deliver the required dose, these unites can be filled into sachets, capsules or compressed into tablet

Microparticles and Macroparticles

✓ Particles having diameter between 3 – 800µm are known as microparticles or microcapsules or microspheres

✓ Particles larger than 1000µm are known as Macroparticles

Classification

Microparticle

1. Microcapsule

2. Microsphere

Introduction

✓ Microencapsulation is a process by which very tiny droplets or particles of liquid or solid material are surrounded or coated with a continuous film of polymeric material

✓ The product obtained by this process is called as micro particles, microcapsules

Microencapsulation

• In the encapsulate, the active portion is termed the core, internal phase, or fill

• The encapsulating material is called the shell, coating, or wall material and may range in both its thickness and number of layers

• Microcapsules can release their contents at controlled rates at specific conditions

• Shape – ideally spherical; however, their shape is heavily influenced by the structure of the unencapsulated material

Advantages of Microencapsulation

✓ To Increase of bioavailability

✓ To alter the drug release

✓ To improve the patient’s compliance

✓ To produce a targeted drug delivery

✓ To reduce the reactivity of the core in relation to the outside environment

✓ To decrease evaporation rate of the core material.

✓ To convert liquid to solid form

✓ To mask the core taste

Fundamental Consideration

Applications of Microencapsulation

Chemistry

Printing & recording

Carbonless paper,

Adhesives

Pigments and

Fillers Catalysts

Food & feed

Aromas, Probiotics

Unsaturated oil,

Enzyme food processing amino acid for cows

Agriculture

Fungicide – herbicide,

Insect repellent,

Biopesticide

Pigments and fillers

Artificial insemination

Biotechnology & environment

Continuous reactor,

Shear protection,

Reactor oxygenation

Consumer & diversified

Cosmetics, detergents (enzymes), sanitary (active, aromas)

Carbonless copy paper

Release Mechanisms of Microencapsulation

1. Degradation-controlled monolithic system

2. Diffusion-controlled monolithic system

3. Diffusion-controlled reservoir system

4. Erosion

Microencapsulation: Techniques

Air suspension technique

Single & double emulsion

Pan coating

Coacervation

Solvent evaporation

Spray drying and spray Congealing

Polymerization

Extrusion

Air Suspension Techniques (Wurster)

Wurster Process

Microencapsulation by air suspension technique consist of:

• Dispersing of solid, particulate core materials in a supporting air stream

• Spray coating the air suspended particles

• Within the coating chamber, particles are suspended on an upward moving air stream

– The air may be heated or cooled

• The design of the chamber and its operating parameters effect a recirculating flow of the particles through the coating zone portion of the chamber, where a coating material, usually a polymer solution, is spray applied to the moving particles

– The coating, which may be in a molten state or dissolved in an evaporable solvent

• During each pass through the coating zone, the core material receives an increment of coating material

• The cyclic process is repeated, perhaps several hundred times during processing, depending on

– The purpose of microencapsulation

– The coating thickness desired

– Whether the core material particles are thoroughly encapsulated

• The supporting air stream also serves to dry the product while it is being encapsulated

• Drying rates are directly related to the volume temperature of the supporting air stream.

• The coating is atomised through nozzles into the chamber and deposits as a thin layer on the surface of suspended particles

• The turbulence of the column of air is sufficient to maintain suspension of the coated particles, allowing them to tumble and thereby become uniformly coated.

• Upon reaching the top of the air steam, the particles move into the outer, downward-moving column of air, which returns them to the fluidised bed with their coating nearly, dried and hardened

• The particles pass through the coating cycle many times per minute

• With each successive pass, the random orientation of the particles further ensures their uniform coating

• The process typically takes from 2 to 12 hours to complete and achieves exceptionally good coverage, leaving only about 0.2-1.5% of the particles uncoated

• Air suspension coating can be used with core particles ranging from 50 to 500 µm

Various variables to be considered during this process are:

• Volume of the air required to fluidize and support the core

• Coating material application rate and its concentration

• Amount of coating material required

• Temperatures of the inlets and outlets

• Various parameters of core material such as its melting point, density, surface area, friability, volatility, crystallinity, flow ability and solubility.

MICROENCAPSULATION BY COACERVATION PHASE SEPARATION TECHNIQUE

Coacervation

• Bungenberg and colleagues defined as, partial desolvation of a homogeneous polymer solution into a polymer-rich phase (coacervate) and the poor polymer phase (coacervation medium)

• The term originated from the Latin ‘coacervate’, meaning “heap”

• This was the first reported process to be adapted for the industrial production of microcapsules

Coacervation – Methods

Simple coacervation – A desolvation agent is added for phase separation

Complex coacervation – Involves complexation between two oppositely charged polymers.

Microencapsulation – Coacervation Technique

STEP 1: Formation of three immiscible phases

• A liquid manufacturing phase

• A core material phase

• A coating material phase

STEP 2: Deposition of the liquid polymer coating on the core material

STEP 3: Rigidizing the coating usually by thermal, cross linking or desolvation techniques to form a microcapsule

STEP 1: Formation of three immiscible phases

1. Liquid manufacturing vehicle

2. Core material

3. Coating material

• The core material is dispersed in a solution of the coating polymer

The three phases are formed by;

Simple coacervation

• Temperature change

• Salt addition

• Nonsolvent addition

• Incompatible polymer addition

Complex coacervation

• Polymer – polymer interaction

1. Changing temperature of polymer solution

e.g. ethyl cellulose in cyclohexane (N-acetyl P-amino phenol as core)

2. Addition of salt

e.g. addition of sodium sulphate solution to gelatine solution in vitamin encapsulation

3. Addition of non-solvent

e.g. addition of isopropyl ether to methyl ethyl ketone solution of cellulose acetate butyrate

4. Addition of incompatible polymer to the polymer solution

e.g. addition of polybutadiene to the solution of ethylcellulose in toluene

5. Inducing polymer – polymer interaction

e.g. interaction of gum Arabic and gelatin at their iso-electric point

Step 2: Deposition of liquid polymer upon the core material

• Accomplished by controlled, physical mixing of the coating material (while liquid) and the core material in the manufacturing vehicle

• Polymer should be adsorbed at the interface formed between the core and the liquid phase

• Adsorption phenomenon is a pre requisite for effective coating

Step 3: Rigidization of the coating

Carried out by

Crosslinking

Desolvation

Thermal treatment

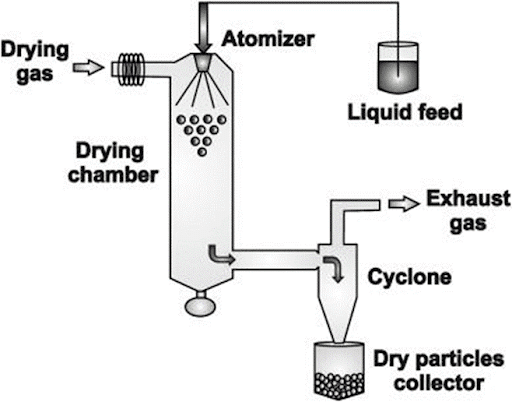

MICROENCAPSULATION BY SPRAY DRYING AND SPRAY CONGEALING

Dispersing the core material in a liquefied coating substance

â

Spraying or introducing the core coating mixture into suitable environmental condition

â

Rapid solidification of the coating

Rapid solidification of the coating

Spray drying – Rapid evaporation of a solvent in which the coating material is dissolved à Coating solution dissolved in a solvent

Spray Congealing – Thermally congealing a molten coating material or by solidifying a dissolved coating by introducing the coating core material mixture into a nonsolvent à Coating applied as a melt of waxes, fatty acids, polymers and sugars that are solids at room temperature but melt at reasonable temperature

5 to 600 microns

Spray dryer

Equipment

➢ Spray drier

Process control variables

➢ Viscosity, uniformity, concentration of core and coating material

➢ Feed rate

➢ Method of atomization

➢ Drying rate

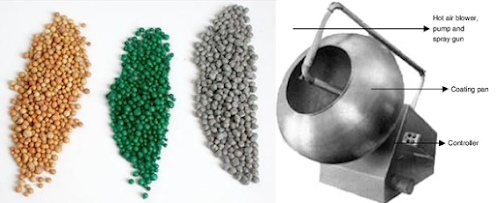

MICROENCAPSULATION BY PAN COATING

Pan Coating

• Microencapsulation of relatively large particles

• Particles larger than 600 microns

• Controlled release beads

• Coating solution atomized on the particles in the coating pan

• Solvent removed by passing warm air over the coated particles

• Or by drying in an oven

MICROENCAPSULATION BY SOLVENT EVAPORATION

Solvent evaporation

Drug Dissolved or dispersed in Solution of polymer in a volatile solvent à Dispersed àLiquid manufacturing vehicle à Removal of solvent

Process variables → solvent for the polymer, temperature cycle, agitation rates

MICROENCAPSULATION BY POLYMERIZATION

Interfacial Polymerization

• Reaction of monomeric units located at the interface existing between a core material and continuous phase

Coating Materials

Water soluble resin

• Gelatin

• Gum Arabic

• PVP

• CMC

• Methyl cellulose

• Arabinogalactan

• Polyvinyl acrylate

• Polyacrylic acid

Water insoluble resin

• Ethyl cellulose

• Polyethylene

• Polymethacrylate

• Cellulose nitrate

• Silicones

Wax & lipid

• Paraffin

• Carnauba wax

• Bees wax

• Stearic acid

• Stearyl alcohol

Enteric resin

Shellac

Zein

Cellulose acetate phthalate

APPLICATIONS OF MICROENCAPSULATION

Pharmaceutical Applications

• To improve the flow properties. e.g. Thiamine, Riboflavine

• To enhance the stability. e.g. Vitamins

• To reduce the volatility of materials. e.g. Peppermint oil, Methyl salicylate

• To avoid incompatibilities. e.g. Aspirin and Chloramphenicol

• To mask the unpleasant taste and odour. e.g. Aminophylline, castor oil

• To convert liquids into solids. e.g. Castor oil, Eprazinone,

• To reduce gastric irritation. e.g. Nitrofurantoin, Indomethacin

Microencapsulation in paint industry

• Products such as acrylics, powder coatings, urethane paints are key product types currently used with microencapsulation

Thermo-chromic & photo-chromic apparels/fabrics

• These fabrics change colour as an effect of change in temperature in the surrounding

• Within the fabric, the microencapsulated colourings are responsive to thermal changes and light sensitive changes.

Carbonless Paper

• With carbonless paper, the copy is produced by a chemical reaction between two different coatings (Color producing substance and reacting substance), which are generally applied to the front and back of a base paper

• This color reaction is caused by pressure (typewriter, dot-matrix printer, or writing instrument).

Microencapsulated Scents

• Microcapsules containing fragrances (essential oils) are applied to paper

• They stay enclosed in the (micro) capsule until pressure force is applied, under which microcapsule shell ruptures and releases the core material

• These microcapsules are mostly used in “scratch-n-sniff” applications e.g. samples perfume inserts in the newspapers and magazines, promotional advertising campaigns, etc.

Food industry

• Microencapsulated flavors, lipids, and pigments

• Microencapsulation of coffee flavors improves the protection from light, heat and oxidation when in the dry state, but the core is released upon contact with water

• Microencapsulated L. acidophilus in cheese

• Microencapsulated probiotics by emulsification in alginate-chitosan, demonstrating more resistance in simulated gastrointestinal conditions

• Encapsulated aspartame – improving the protection even at 80°C.

Agriculture

• Controlled Release of Crop Protection Products – a pesticide product may be most effective at certain humidity or pH levels, or need to be targeted to the leaves or the roots of the plant

• Sophisticated encapsulation technologies can be designed with appropriate triggers for maximum efficacy. A pesticide that works on the leaves of the plant, for example, may be triggered by UV exposure. Another agrichemical that needs to be applied to the roots in wet conditions may only be released when rain washes it down into the soil

TOP COMPANIES IN THE MICROENCAPSULATION MARKET

Encapsys, LLC

• Provides microencapsulation solutions for paints and coatings, agriculture, oil and gas, adhesives and sealants, personal and household care, and paper industries.

Reed Pacific Pty Limited

• Provides microencapsulation technology for many different applications such as

– Insect repellent

– Healthcare

– Agriculture

– Consumer products (fabric care and personal care)

– Cosmetic & skin care

– Industrial actives

– Defense & aviation

Ronald T. Dodge Company

• The company offers services such as microencapsulation, fragrance delivery, controlled release, encapsulated products, conservation, scented coatings, and inks

GAT Microencapsulation GmbH

• Generic agrochemical products (agro-generics) and biocidal products such as herbicides, insecticides, acaricides, fungicides, and biocides

Capsulae

• The company offers microencapsulation for human and animal nutrition, biotechnologies, and chemical industries by using dripping technology, emulsion-based technology, and coating technology

Microtek Laboratories, Inc.

• Microencapsulated materials are utilized in agriculture, pharmaceuticals, foods, cosmetics and fragrances, textiles, paper, paints, coatings and adhesives, printing applications, and many other industries

Aveka, Inc.

• It offers custom particle processing, manufacturing, powder process research and development, consulting, prilling, spheroidization, dry powder coating, and encapsulation services.

TasteTech Ltd.

• The company offers core-shell encapsulation, matrix encapsulation, spray drying, power stabilization, flavor development, and contract manufacturing services. The company serves bakery, chewing gum, confectionery, and sports nutrition markets.

LycoRed Ltd.

• Develops and supplies premixes and microencapsulated carotenoids, vitamins, minerals, and specialty ingredients for dietary supplementation, food fortification, coloring, and flavor enhancement applications

Innobio Limited

• The company provides specialty fatty acids, carotenoids, and branched-chain amino acids

• It offers its product to health concerning markets such as sport nutrition, weight management, eye health, cognition, vascular care, and anti-aging

Summary

• Microparticles are a kind of multi-particulate dosage forms

• Microparticles can be in the form of microspheres or microcapsules

• Microencapsulation if the process of applying polymer coatings to tiny droplets or particles of liquid or solid material

• Microencasulation has several advantages in biomedical, pharmaceutical and other fields

• Microencapsulation by air suspension (Wurster) coating involves application of polymer coat to particles suspended in a stream of air

• Coacervation – Simple and complex

• Steps – Formation of three phases, deposition of coat, rigidization of coat

• Pan coating – for larger particles

• Solvent evaporation – for organic solvent for polymer

• Spray drying and congealing – by atomizing polymer, core, solvent mixture in a suitable polymer

• Interfacial polymerization – Reaction of monomeric units located at the interface existing between a core material and continuous phase

Microencapsulation can be applied to all sectors of industrial activity

1. Food & Feed

• Flavouring agents & sweeteners

• Enzymes & micro-organisms

• Vitamins, minerals & amino acids

• Plant extracts, aromas, fragrances

• Unsaturated fatty acids

2. Agriculture & Environment

• Insecticides and fungicides

• Herbicides and fertilizers

• Repellents and larvicides

• Plant biocontrol & bionutrition

• Water, soil, air treatment

3. Human & Animal Health

• Vaccination & drug delivery

• Artificial insemination

• Bioartificial organs

• Cell therapy

4. Chemistry

• Adhesives and sealants

• Paints and coatings

• Building & construction materials

• Self-healing materials & PCM

5. Home & Personal Care

• Cosmetic creams

• Shampoo, toothpaste, soap & shower gels

• Washing powders & washing-up liquids

• Household products

For PDF Notes Click on Download Button