Quality by

Design (QbD) in Product Development

v Systematic,

holistic and proactive approach to pharmaceutical development.

v Begins

with predefined objectives

v Emphasizes

product and process understanding and process control

v Based

on sound science and quality risk management

Ref.: ICH Q8 (R2)

Generic industry business model: Regulator’s perspective

v File

first, learn later

v Major

amendments during review process

– Exhibit batch stability

failure, formulation revision

v Longer

time for generic product approval

v Approved

product may not be marketed

v Post

approval changes – prior approval supplements

How QbD will help improve?

v Ensure

higher level of assurance of product quality for patient

Ø Improved

product and process design & understanding

Ø Monitoring,

tracking & trending of product & process.

v More

efficient regulatory oversight

v Efficiency

and cost saving for industry

Ø Increase

efficiency of manufacturing process

Ø Minimize

/ eliminate potential compliance actions

Overview of QbD

Quality Target Product

Profile à Product Design and Understanding à Process Design and Understanding à Control Strategy à Continuous Improvement

v Quality

Target Product Profile (QTPP)

v Define

Critical Quality Attributes (CQAs)

v Perform

risk assessment

v Link

raw material attributes and process parameters to CQAs

v Design

and implement a control strategy

v Manage

product lifecycle, including continuous improvement

Quality Target Product Profile-QTPP

What is QTPP?

• A

set of elements that defines the drug product

• The

target or goal set in advance

• A

guide to Drug Product development

What forms the basis for QTPP?

• The

RLD and its label

• Applicable

regulatory guidelines

When to define QTPP?

• At

the start of development

• Knowledge

gained in development may change some elements

Components of QTPP

Components related to safety, efficacy, identity, purity and

potency

Critical and non-critical components, e.g.

• Critical:

Assay, content uniformity

• Non-critical:

Appearance

Fixed and variable components

• Fixed

elements must be present

e.g. Dosage form, strength

• Variable

elements may have a range of acceptable values

e.g. Tablet weight, assay

QTPP components for IR tablet – Example

Dosage Form |

Route of administration |

Strength |

Weight |

Pharmacokinetics |

Appearance |

Identity |

Assay |

Impurities |

Content uniformity |

Friability |

Dissolution |

Residual solvents |

Specific requirements in QTPP

v Scored

tablets

Ø Weight

variation between two halves

Ø Dissolution

of half tablet

v Orally

Disintegrating tablets

Ø Hardness

Ø Disintegration

time

Ø Container

closure

v Extended

Release products

Ø Alcohol

induced dose dumping

Critical Quality Attributes – CQAs

v CQAs

are a subset of the QTPP

v Include

critical parameters that are likely to change based upon variations in raw

materials and processes

-Identity

test for dosage form – Not a CQA

-Assay,

Content uniformity – CQAs

v CQAs

are monitored throughout the DP development.

v CQAs

ensure that DP remains within safe and effective levels.

QTPP and CQAs

QTPP components |

Dosage Form |

Route of administration |

Strength |

Weight |

Pharmacokinetics |

Appearance |

Identity |

Assay |

Impurities |

Content uniformity |

Friability |

Dissolution |

Residual solvents |

â

CQAs |

Assay (efficacy) |

Impurities (safety) |

C.U. (efficacy) |

Dissolution (efficacy) |

QTPP and Specifications

QTPP

• Desired

target for developmental work

• Components

of QTPP may or may not be in specification

–

Not in spec – Dosage form, strength

–

In spec – Assay, impurities

• Does

not include acceptance criteria

Specifications

• Includes

all of the CQAs

• Specification

is a list of

–

tests,

–

references to analytical procedures

–

acceptance criteria

• Establishes

the set of criteria to which DP should conform to be considered acceptable for

its intended use

• Defining

a QTPP does not mean setting all acceptance criteria

• or

the product specifications before development work begins.

QbD Tools – Risk Assessment

Why risk assessment in product development?

v To

identify relative risk levels at the beginning of product development

v To

prioritize limited development resources

v To

document the decision making process throughout development

v To

assess the needs of additional studies for scale up and technology transfer

v To

identify appropriate specifications, critical process parameters and

manufacturing controls

v To

decrease variability of critical quality attributes

Risk Assessment

Risk assessment for

• Formulation

– starting material properties, levels of components

• Manufacturing

process

Steps for risk assessment

• List

out all components / processes

• Prepare

the process flow chart

• Identify

all potential failure modes for each item with risk query (what might go

wrong?)

• Risk

analysis

• Risk

evaluation

Various formal methodologies available for risk assessment

v Failure

Mode Effects Analysis & Failure Mode Effects & Criticality Analysis

v Hazard

& Operability Analysis

v Supporting

statistical tools

• It

is neither always appropriate nor always necessary to use a formal risk management

process….. The use of informal risk assessment processes can also be considered

acceptable. – ICH Q9

• A

risk-based justification based on experience and data is always necessary!

Quality by Design for ANDAs:

An Example for Immediate-Release Dosage Forms

v Generic

product development for Acetriptan Tablets, 20 mg.

v Acetriptan

is a BCS Class II compound displaying poor aqueous solubility (less than 0.015

mg/mL) across the physiological pH range.

v It

exists in three different polymorphic forms which may affect dissolution.

v Polymorph

III is the most stable polymorph.

v Drug

product is prepared with roller compaction process.

Risk assessment for formulation components

Drug Product CQA | Formulation Variables | ||||

Drug Substance PSD | MCC/Lactose Ratio | CCS Level | Talc Level | Magnesium Stearate Level | |

Assay | MEDIUM | MEDIUM | LOW | LOW | LOW |

Content Uniformity | HIGH | HIGH | LOW | LOW | LOW |

Dissolution | HIGH | MEDIUM | HIGH | LOW | HIGH |

Degradation Products | LOW | LOW | LOW | LOW | MEDIUM |

Risk assessment of DP manufacturing process

Drug Product CQAs | Process Steps | ||||

Pre-RC* Blending and Lubrication | Roller Compaction | Milling | Final Blending and Lubrication | Compression | |

Assay | MEDIUM | LOW | MEDIUM | LOW | MEDIUM |

Content Uniformity | HIGH | HIGH | HIGH | LOW | HIGH |

Dissolution | MEDIUM | HIGH | MEDIUM | HIGH | HIGH |

Degradation Products | LOW | LOW | LOW | LOW | LOW |

Justification for assigned risks

Process Steps | Drug Product CQAs | Assigned Risk | Justification |

Pre-Roller Compaction Blending and Lubrication | Assay | MEDIUM | Suboptimal pre-roller compaction blending and |

Content Uniformity | HIGH | The PSD and cohesiveness of the drug substance | |

Dissolution | MEDIUM | Blending process variables may impact the distribution | |

Degradation Products | LOW | Blending process variables are unrelated to the |

CMAs, CPPs and CQAs

What factors affect drug product CQAs?

v Properties

of Input Materials- Identify Critical Material Attributes (CMAs)

v Properties

of in-process materials- CQAs of one step become CMAs for a downstream unit operation

v Manufacturing

process parameters- Identify Critical Process Parameters (CPPs)

Critical Material Attributes (CMAs)

Risk Assessment of the drug substance attributes

Drug Product CQAs | Drug Substance Attributes | |||||

Solid State Form | Hygroscopicity | Particle Size | Residual Solvents | Process Impurities | Chemical Stability | |

Physical Attributes (size and splitability) | LOW | LOW | LOW | LOW | LOW | LOW |

Assay | LOW | LOW | LOW | LOW | LOW | LOW |

Content Uniformity | LOW | LOW | LOW | LOW | LOW | LOW |

Drug Release | HIGH | LOW | HIGH | LOW | LOW | LOW |

Solid state form and particle size of DS are CMAs

CPPs

• Risk

assessment of manufacturing process

• Identify

high risk steps (unit operation) that affect the CQAs of DP.

Drug Product CQAs | Process Steps | ||||

Pre-RC* Blending and Lubrication | Roller Compaction | Milling | Final Blending and Lubrication | Compression | |

Assay | MEDIUM | LOW | MEDIUM | LOW | MEDIUM |

Content Uniformity | HIGH | HIGH | HIGH | LOW | HIGH |

Dissolution | MEDIUM | HIGH | MEDIUM | HIGH | HIGH |

Degradation Products | LOW | LOW | LOW | LOW | LOW |

Process Step: Compression

CPPs | DP CQAs | Risk Assessment | Justification and Strategy |

Main compression force | Content Uniformity | LOW | CU is dominated by BU and flowability and is unrelated to |

Dissolution | HIGH | Suboptimal compression force may affect tablet hardness | |

Press speed (dwell time) | Content Uniformity | HIGH | A faster than optimal press speed may cause inconsistent |

Dissolution | HIGH |

Control Strategy

“A planned set of controls, derived from current product and

process understanding that ensures process performance and product quality…..”

ICH Q8 (R2) & Q10

Control Strategy includes following elements (but not

limited to):

• Input

material attributes (e.g. drug substance, excipients, container closure)

• Equipment

operating conditions (process parameters)

• In-process

controls

• Finished

product specifications

• Controls

for each unit operations

• Methods

and frequency of monitoring and control.

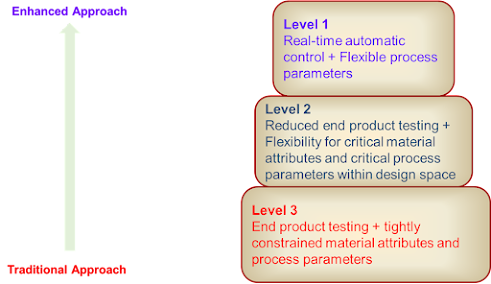

Control Strategy Implementation Options

QbD Tools – DoE

Design of experiments (DoE)

• Useful

for screening of variables with significant impact on DP CQAs

• Classical

approach uses OFAT (One Factor At A Time)

• Limited

number of experiments gives limited information.

• DoE

helps study effects of interaction of multiple factors at a time

• Used

in optimization studies, enables creation of “design space”

• “Design

space” is proposed by the applicant and subject to regulatory assessment and

approval.

• “Design

space” developed at lab or pilot scale can be proposed for commercial scale,

but needs to be verified at production scale for scale dependant parameters.

Process Analytical Technology (PAT)

Ø Timely

measurements during processing

v Critical

quality and performance attributes

v Raw

and in-process materials

Ø At-line,

on-line or in-line measurements

• Founded

on “Process Understanding”

Opportunities for improvement

• More

reliable and consistent processes (& product)

• Less

failures, less reworks, less recalls

• Flexibility

w.r.t. scale and equipment

• Better

/ faster Quality Systems

• Process

Enhancement Opportunities

PAT in Tablet manufacturing

Stage | Technique | Measurement |

Dispensing | NIR / Raman | Identification of raw materials |

Wet Granulation | NIR | Moisture distribution |

Drying | NIR | Moisture content |

Blending | NIR | Blend Uniformity |

Compression | Strain gauges | Compression force |

NIR | Content Uniformity |

PAT Examples

Spectral Probe NIR Analyzer installed on viewing window of

Glatt FBD without any dryer modification.

Real-time Blend

Uniformity by using TruProcess™ Analyzer

QbD: Required or Optional?

Required

• Quality

target product profile (QTPP) including critical quality attributes (CQAs) of

the drug product and including Product design and understanding

• Product

design and understanding

• Critical

material attributes (CMAs) of the drug substance and excipients

• Process

design and understanding

• Critical

process parameters (CPPs)

• Control

strategy, including justification

Optional

• Design

Space

• Process

Analytical Technology

References for QbD

- Guidance

for Industry: Q8(R2) Pharmaceutical Development - Guidance

for Industry: Q9 Quality Risk Management - Guidance

for Industry: Q10 Pharmaceutical Quality System - Guidance

for Industry PAT: A Framework for Innovative Pharmaceutical Development,

Manufacturing, and Quality Assurance - Quality

by Design for ANDAs: An Example for Modified Release Dosage Forms - Quality

by Design for ANDAs: An Example for Immediate Release Dosage Forms - GPhA

presentations - Draft

QbR updated