Fermentation Process of Penicillin

Fermentation Process of Penicillin

Objectives

At the end of the lecture, student will be able to

• Discuss the mechanism of action and adverse effects of Penicillin

• Explain the fermentation process of Penicillin

Penicillin

• First antibiotic – scottish scientist – Alexander Fleming – 1928

• PCN – isolated from fungus – Penicillium notatum

• ß-lactum antibiotics

• Active against – Gram +ve bacteria (Staphylococci and Streptococci) not against gram –ve except at high dose

Mechanism of Action

• Interferes with the cell wall synthesis of bacteria

• Inhibit the formation – peptidoglycan cross links in bacterial cell wall – binding of ß-lactum ring of penicillin to enzyme DD-transpeptidase

• DD-transpeptidase – cannot catalyze – formation of cross links – imbalance in cell wall production – degrades – rapid cell death

Adverse effects

• 10 % people – allergic reactions

• ≥ 1% of people – diarrhoea, hypersensivity, nausea, rashes, neurotoxicity and urticaria

• Pain and inflammation at the site of injection

• 0.1- 1% – fever, vomiting, erythema, dermatitis, seizures

Route of Administration:

• Oral

• IV

Use:

• Otitis Media

• Meningitis

• Sore Throat

• Pneumonia & Respiratory Infection

• Septicemia

• Peritonitis

• Gonorrhea

• UTI

Known Issues

• Resistance (B-lactmase & other mechanisms) Allergic rxns

• Cross-hypersensitivity (1-3% w/cephalosporins)

Classification of Penicillin

Production of Penicillin

• Stationary mat culture

• Medium – sterilized – shallow layers – bottles, flasks, trays or pans – glass or metal

• Wet or dry spores – added – medium or blown on its surface

• Incubated – 24 – 28˚C for six or seven days

• Equipment and labor required

• Harvest – pooling all the broths – but contaminated (penicillinase enzyme) – separated and discarded

• Problems –Low yield

– Oxygen penetration is low

– Portion of mycelium submerged – medium – deficient in O2

– Aerial hyphae – poor access to nutrients

• If not – penicillinase – will destroy all the pooled penicillin

• Deep tank aerated fermentation – World War II

Fermentation Process

• Several different fungi are used

• Principal organism used – commercial production – Mutated strains – Penicillium chrysogenum

Media Composition (Jackson, 1958)

Trade secrets

• Cornsteep liquor solids – 3.5 %

• Lactose – 3.5 %

• Glucose – 1 %

• Calcium carbonate – 1 %

• Potassium dihydrogen phosphate – 0.4 %

• Edible oil – 0.25 %

• Penicillin precursor

Production media: (Sylvester and Coghill, 1954)

• Corn steep liquor solids – 30 gm

• Lactose – 30 gm

• Glucose – 5 gm

• Sodium nitrate – 3 gm

• Magnesium sulphate – 0.25 gm

• Zinc sulphate – 0.044 gm

• Calcium carbonate – 3 gm

• Penicillin precursor

Step 1: Stock culture Maintenance

• High yielding strains of Penicillium chrysogenum

• Agar media – minimum vegetative growth and rapid sporulation of entire culture

• Media – inoculated – spores

This primary stock can maintained as

• Well-sporulated agar slants – frozen

• Soil stocks are prepared and stored at 2-4˚C

• Lyophilized

Step 2: Inoculum preparation

• Spores – heavily sporulated working stock – suspended in water or dil solution of non-toxic wetting agent, 1:10,000 SLS

• Added to bottles or flasks – wheat bran + nutrient (Inoculum media – similar to production media – except lactose and precursor not added)

• Incubated – 24 ˚C for 5-7 days – to provide heavy sporulation

• Spores – used – inoculate inoculum tanks

• Inoculum tanks – incubated – 24-48 hrs – agitation and aeration – production tank

• Contamination – inoculum tanks – microscopically observations and sub culturing in broth medium

Production of penicillin

• Penicillin fermentation – 25-26

• 3-5 days

• Exact duration depends on

– Fungal strain

– Type of production media

– Aeration and agitation conditions

• Periodic samples – penicillin yield and contamination check – sensitive to penicillinase producing organisms

Course of Penicillin Production

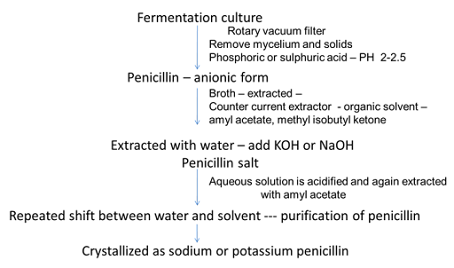

Harvest and Recovery

Summary

• Principal organism used – commercial production – Mutated strains – Penicillium chrysogenum

• Penicillin fermentation – 25-26

• 3-5 days

• Exact duration depends on

– Fungal strain

– Type of production media

– Aeration and agitation conditions

• Periodic samples – penicillin yield and contamination check – sensitive to penicillinase producing organisms

Also, Visit: Biotechnology Notes