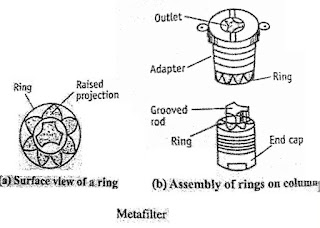

Metafilter

Principle

• Mechanism is surface filtration

• In this, metal rings contain semicircular projections,

which are arranged as a nest to form channels on the edges

• This channel offers resistance (strainer) to the flow of

solids (coarse particles)

• The clear liquid is collected into receiver from the top

Construction

• Metafilter consists of a series of metal rings

• These are threaded so that a channel is formed on the

edges

• It contains a grooved drainage column on which a series of

metal rings are packed

• These rings are

usually made up

of stainless steel

and have dimensions

of about 15.0

mm internal diameter and 22.0 mm

external diameter

• Each metal ring has a number of semicircular projections

(0.8 mm in thickness) on one side of surface

• The projections are arranged as a nest to form channels on

the edges

• These rings are tightened on the drainage column with a

nut

• Metafilters are also known as edge filters

Diagram of

metafilter

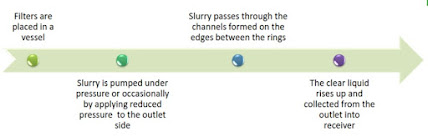

Working

For separation of fine particles, a bed of suitable

materials such kieselguhr is first built up.

The pack of rings serves essentially as a base on which the

true filter medium is supported.

Advantages

• Can be used under high pressures, without any danger of

bursting the filter medium

• Running cost are low, as separate filter medium is not

used

• Can be constructed

from a material

that can provide

excellent resistance to

corrosion and avoid contamination of sensitive products

• It is extremely versatile filter because fine as well as

large both type of particles can be separated

• Removal of cake can be carried out by simply back-

flushing with water

• Change over from one batch to another or one product to

another is easy

• Sterile products can be handled

Uses

Meta filters can be used for –

·

Clarification of syrups

·

Filtration of injection solutions

·

Clarification of insulin liquors

·

Filtration of viscous liquids can be achieved by

applying pressure