Mixing and Homonization

Mixing and Homonization

Mixing

Mixing is defined as a process that tends to result in a randomization of dissimilar particles within a system

• The term mix means to put together in one mass

• The term blending means to mix smoothly and inseparably together during which a minimum energy is imparted to the bed

• The terms mixing and blending are commonly used interchangeably in the pharmaceutical industry Mixing is an unit operation in which two or more components in separate or roughly mixed conditions are treated so that each particles lies as nearly as possible in contact with a particle with a particle of each of the other ingredients

Mixing may be defined as a unit operation that aims to treat two or more components, initially in an unmixed or partially mixed state, so that each unit (particle, molecule etc.) of the components lies as nearly as possible in contact with a unit of each of the other components

Mixing is a process that tends to result in a randomization of dissimilar particles within a system

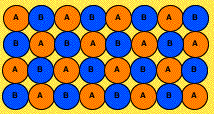

Mixing Pattern

• Incorrect Situation

• Correct Situation

Importance of mixing

1. To make simple physical mixture In the production of tablets, capsules, sachets and dry powders two or more powders or granules are mixed

2. Physical change Mixing may aim at producing a change that is physical, for example the solution of a soluble substance. In case of dissolving a solid in a solvent mixing will take place by diffusion but the process will be slow. In this case agitation makes the process rapid

3. Dispersion In case of emulsions and creams two immiscible liquids are mixed where one liquid is dispersed into other. In suspension and pastes solid particles are dispersed in a liquid by mixing.

4. Promotion of reaction Mixing encourages and controls a chemical reaction, so ensuring uniform products

Objectives

Homogeneity

Promote physical change

* Diffusion

* Dissolution

Facilitate Dispersion

Promote chemical reaction

Applications of mixing

• Mixing is an intermediate stage in the preparation of several dosage forms

• Wet mixing in the granulation step in the production of tablet and capsules

• Dry mixing of several ingredients ready for direct compression of tablet

• Dry blending of powder in capsule, dry syrup and compound powder (insufflations)

• Production of pellets for capsule

Types of mixtures

Positive mixtures – Positive Mixtures (Miscibility) Irreversible

Positive mixtures are formed from materials such as gases or miscible liquids which mix spontaneously and irreversibly by diffusion, and tend to approach a perfect mix.

Example: Sugar in water, Alcohol in water

Negative mixtures – Mixtures (Immiscibility) (Separates if energy applied is withdrawn)

With negative mixtures the components will tend to separate out. If this occurs quickly, then energy must be continuously input to keep the components adequately dispersed, e.g. with a suspension formulation, such as calamine lotion.

Suspension

Emulsion

Neutral mixtures – (Neither mixing nor Demixing)

Neutral mixtures are said to be static in behavior, i.e. the components do not tend to mix spontaneously or segregate spontaneously once work has been input to mix them.

Examples: Ointment, Paste, Powders

Types of mixing

1. Solid-solid mixing

2. Liquid-liquid mixing

3. Mixing of immiscible liquids

4. Solid-liquid mixing

Mixing Pattern

Mechanism of Mixing

Mechanism of Mixing

A) Liquid Mixing

1) Bulk Transport-Movement of large portion of a material from a one location to another location in a given system.

2) Laminar/Streamline –Mixing of 2 dissimilar liquids through laminar flow.

3) Turbulent Mixing- Mixing due to turbulent flow.

4) Molecular Diffusion-mixing at molecular level in which molecules diffuse due to thermal motion.

B) Solid Mixing

1) Convective Mixing-Inversion of powder bed using blades or peddles. A large mass of material moves from one art to another (Macromixing).

2) Diffusion mixing-Involves random motion of particles within the powder bed (Micromixing).

3) Shear Mixing-The forces of attraction are broken down so that each particle moves on its own between regions of different composition and parallel to their surfaces.

Degree of mixing

• Ideal mixing or perfect mixing: Mixing process will never yield an ideal or perfect mixture.

• Acceptable mixing:

1. Random mixing – Same ratio of components ——–> in the entire mixture.

2. Ordered mixing – It involves the use of following forces

– Mechanical means of ordered mixing

– Adhesion means of ordered mixing

– Coating means of ordered mixing

• Mechanical means of ordered mixing –

The mass of each ingredient is divided and recombined a number of times in the powdered bed.

Adhesion means of ordered mixing –

These forces of particles may create ordered units of nearly identical composition depending on the process. Use of binding agent during wet granulation.

Coating means of ordered mixing –

Particles in the assemblage may also be coated with other ingredients to give an ordered mix either as individual or coated particle agglomerates.

Factor affecting powder mixing

1) Particle size Easy to mix similar sized powders

2) Particle Shape Ideal shape is spherical. Irregular shape leads to inter locking- once mixed difficult to segregate.

3) Particle attraction Due to electrostatic charges can leads to separation

4) Material Density Dense material moves downwards

5) Proportion of materials Best mixing when ratio is 1:1

Other case always mixing is done in the ascending order of their weights

Mixing indices

• The mixing index involves the Comparison of Standard Deviation of sample of mixture under study with the estimated Standard Deviation of a completely random mixture.

• The ratio will be less than 1.

• The higher the M value, the greater homogeneity

Solid Mixing

Selection Criteria

1. Powder bed should not be filled for more than 60 %

2. Particles should be subjected to movement in three directions

3. Shearing force should be sufficient to prevent aggregation

4. There should be no centrifugal effect

5. Forces should not cause breakage of the particles

Classification of equipment for solid mixing

• Based on flow properties

1. Free flowing solids

e.g.: V cone blend, Double cone blender

2. Cohesive solids

e.g.: Sigma blender, Planetary mixer

• Based on scale of mixing

1. Batch type (small scale)

e.g.: Mortar and pestle, V cone blender, Double cone blender, Ribbon blender, Sigma blender, Planetary paddle, Fluidized mixer

2. Continuous type (large scale)

e.g.: barrel type, zigzag type

| S.no. | Nature of mixer | Examples | Mechanism of mixing |

| 1 | Batch type | Mortar pestle | Trituration |

| 2 | Tumbling mixers or cylindrical mixers with no mixing blade | Double cone blender, V cone blender | Tumbling action |

| 3 | Tumbling mixer with a mixing blade

| V cone blender Double cone blender | Tumbling action as well as shearing with blade |

| 4

| Static mixers

| Ribbon blender Sigma blender Planetary paddle | Stationary shell and rotating blade |

| 5 | Air mixers or fluidized mixers | Fluidized mixer | Air supported blending |

| 6 | Continuous type

| Barrel type Zigzag type | Rotating shell with rotating blade |

Ribbon blender

Principle

Mechanism of mixing is shear

Shear is transferred by moving blades. High shear rates are effective in breaking lumps and aggregates. Convective mixing also occurs as the powder bed is lifted and allowed to cascade to the bottom of the container. An equilibrium state of mixing can be achieved.

Construction

• Consists of horizontal cylindrical trough usually open at the top. It is fitted with two helical blades, which are mounted on the same shaft through the long axis of the trough.

• Blades have both right and left hand twists.

• Blades are connected to fixed speed drive.

• It can be loaded by top loading and emptying is done through bottom port.

Working

• Through fixed speed drive, ribbons are allowed to rotate.

• Helical blades moves powders from one end to another.

• One blade moves material in one direction and other moves opposite.

• Close open trough to avoid dusting during dry blending.

• Due to high shear it effectively breaking up lumps and agglomerates.

• Once equilibrium achieved, powder mixture discharge from the bottom

Uses

• Used for mixing of finely divided solids, wet solid mass, and plastic solids

• Uniform size and density materials can be easily mixed

• Used for solid – solid and liquid – solid mixing

Advantages of ribbon blender

• High shear can be applied by using perforated baffles, which bring about a rubbing and breakdown aggregates

• Headroom requires less space

Disadvantages of ribbon blender

• It is a poor mixer, because movement of particles is two dimensional..

• Shearing action is less than in planetary mixer

• Dead spots are observed in the mixer, though they are minimum

• It has fixed speed drive

Sigma Blade Mixer (Z Blade/Double blade/ Kneading Machine)

• It is an example of agitator mixers

• Its shape resemble the Greek letter sigma

• It uses 2 mixer blades

• Sigma blade mixer is a common form used to handle semi-solids of plastic consistency

Principle – shear

Inter meshing of sigma blades creates high shear and kneading action

Construction and working

• It consists of double tough shaped stationary bowl

• Two sigma shaped blades are fitted horizontally in each tough of the bowl

• These blades are connected to a fixed speed drive

• Mixer is loaded from top and unloaded by tilting the entire bowl

• The blades move at different speeds, one about twice than the other, which allows movement of powder from sides to centers

• The material also moves top to downwards and gets sheared between the blades and the wall of the tough resulting cascading action

• Perforated blades can be used to break lumps and aggregates which creates high shear forces

• The final stage of mix represents an equilibrium state

Uses

• Used in the wet granulation process in the manufacture of tablets, pill masses and ointments

• It is primarily used for liquid – solid mixing, although it can be used for solid – solid mixing

Advantages

• Sigma blade mixer creates a minimum dead space during mixing

• It has close tolerances between the blades and the sidewalls as well as bottom of the mixer shell

Disadvantages

• Sigma blade mixer works at a fixed speed

Tumblers or cylindrical blenders

With no mixing blade

• Meant for dry powders

• Equipment consists of a container of any geometric form

• Container is mounted on special roller so that it can be rotated about any axis

• Edge of 27 degrees is good for mixing

• Efficiency of a tumbler mixer highly depends on the speed of rotation. It should be critical and optimum

• Slow rotation- no intense tumbling, No cascade motion, Not enough shear rates are applied

• Rapid rotation-sufficient centrifugal action to the powder to the side of the mixer, more dusting and segregation of fines is possible

• Rate of rotation depends upon size, shape of the tumbler and nature of the material to be mixed. Common range is 30-100rpm

• Mixing is done by tumbling motion, which is accentuated by virtue of the shape of the container

Twin shell blender or V cone blender

• It is V shaped and made up of stainless steel or transparent plastic

• Material is loaded through shell hatches and emptying is normally done through and apex port

• The material is loaded approximately 50-60% of the total volume

• Small models – 20 kg, rotate at 35rpm

• Large models – 1 ton, rotate at 15rpm

• As the blender rotates, the material undergoes tumbling motion

• When V is inverted, the material splits into two portions. This process of dividing and recombining continuously yields ordered mixing by mechanical means

Double cone blender

• It consists of double cone on rotating shaft

• It is usually used for small amount of powders

• It is efficient for mixing powders of different densities

• Material is loaded and emptying is done through the same port

• The rate of rotation should be optimum depending upon the size, shape of the tumbler and nature of the material to be mixed

• The rate of rotation commonly ranges from 30-100 rpm

• Mixing occurs due to tumbling motion

Advantages of V cone blender and double cone blenders

• If fragile granules are to be blended, twin shell blender is suitable because of minimum attrition

• They handle large capacities

• Easy to clean, load, and unload

• This equipment requires minimum maintenance

Disadvantages of V cone blender and double cone blenders

• Twin shell blender needs high headspace for installation

• It is not suitable for fine particulate system or ingredients of large differences in the particle size distribution, because not enough shear is applied

• If powders are free flowing, serial dilution is required for the addition of low dose active ingredient.

Tumbling blenders with agitator mixing blades

Advantages of tumblers with blades

• Baffles are useful for both wet and dry mixing

• Wide range of shearing force can be applied with agitator bars permitting the intimate mixing of very fine as well as coarse powders

• Serial dilution is not needed when incorporating low-dose active ingredients

Disadvantages of tumblers with blades

• Attrition is large, size reduction of friable particles results

• Scale-up can prove a problem, because general principles of scale up do not work

• Cleaning may be a problem, because agitator assembly must be removed and the packing should be replaced for a product changeover

• Potential packing (sealing) problems occur

Planetary mixer

Principle

• Mechanism of mixing is shear

• Shear is applied between moving blade and stationary wall

• Mixing arm moves around its own axis and around the central axis so that it reaches every spot of the vessel

• The plates in the blades are sloped so that powder makes an upward movement to achieve tumbling action also

Construction

• Consists of vertical cylinder shell which can be removed

• The blade is mounted from the top of the bowl

• Mixing shaft is driven by planetary gear and it is normally built with variable speed drive

Uses

• Break down agglomerates rapidly

• Low speeds are used for dry blending and fast for wet granulation

Advantages

• Speed of rotation can be varied at will

• More useful for wet granulation process

Disadvantages

• Mechanical heat is buildup within the powder mix

• It requires high power

• It has limited size and is useful for batch work only

Mixing of Liquids

Mechanism

• Bulk transport: Movement of large portion of a material from one location to another location in a given system. Rotating blades and paddles are used

• Turbulent mixing: Highly effective, mixing is due to turbulent flow which results in random fluctuation of the fluid velocity at any given point within the system. Fluid velocity at a given point changes in 3 directions (X, Y and Z)

• Laminar mixing: Mixing of two dissimilar liquids through laminar flow, i.e., applied shear stretches the interface between them. Suitable for liquids which require moderate mixing

• Molecular diffusion: Mixing at molecular level in which molecules diffuse due to thermal motion

Mixing Apparatus for fluids

• A Container and

• A Mixing Device or Impeller

Mixing Device

• Based on shape and pitch, the are classified into 3 types:

»Propellers

»Turbines

»Paddles

Types of impellers

| Paddles | Turbines | Propellers | |

| Example | Simple Paddle | Curved – Blade | Standard 3- Blade |

| Size | Diameter of paddle is 50-80% of the inside diameter of vessel | Diameter of turbine is 30-50% of the inside diameter of vessel | Diameter of propeller is much smaller in Diameter than paddles or turbines |

| Uses | Suitable for: mixing low viscosity liquids. | Suitable for: mixing viscous liquids, thin pastes and emulsions. | Suitable for:Mixing heavy susps. mixing of thin liquids Dissolution of solids. |

| Rotation speed | 20 – 120 r.p.m. (low speed) | 120 – 200 r.p.m. (moderate speed) | 400 – 1750 r.p.m. (high speed ) |

| Flow type | Tangential & radial | Tangential & radial | Tangential & axial |

| Viscosity | Up to 1000 cp | Up to 100.000 cp | Up to 5000 cp |

Flow patterns of impeller mixers

Flow pattern of the impeller mixers depends on:

1- Liquid properties

2- Type of impeller

3- Size of the mixing tank

4- Presence of baffles and agitators

Flow patterns

1. Tangential (rotational) flow

2. Radial flow

3. Axial or longitudinal flow:

1. Tangential component or circular

Acts in the direction tangent to the circle of rotation around the impeller shaft. If shaft is placed vertically and centrally, tangential flow follows a circular path around the shaft and creates a vortex in the liquid.

2. Radial component

The liquid discharges from the impeller at a right angle to its shaft. Occurs when the centrifugal force produced by the impeller > liquid resistance to flow due to viscosity.

Centrifugal force depends on diameter and speed of impeller.

3. Axial component or longitudinal or vertical

Acts in the direction parallel to the impeller shaft. Longitudinal pattern is best used to generate strong vertical currents particularly when suspending solids are present in a liquid. The liquid discharges parallel to the shaft, either from:

Surface > bottom or bottom > surface.

Axial flow is necessary for liquid containing suspended solids.

| Impeller type | Flow component |

| Propellers | Axial |

| Turbines | Axial or tangential or both |

| Paddles | Radial and tangential |

| Paddles with pitch | Radial, tangential and axial |

Propellers

• It consists of number of blades, generally 3 bladed design is most common for liquids. Blades may be right or left handed depending upon the slant of their blades

• Two are more propellers are used for deep tank

• Size of propeller is small and may increased up to 0.5 metres depending upon the size of the tank

• Small size propellers can rotate up to 8000 rpm and produce longitudinal movement

Advantages of propellers

Used when high mixing capacity is required

Effective for liquids which have maximum viscosity of 2.0 pascals.sec or slurry up to 10 % solids of fine mesh size

Effective gas-liquid dispersion is possible at laboratory scale

Disadvantages of propellers

Propellers are not normally effective with liquids of viscosity greater than 5 pascal.second, such as glycerin castor oil, etc.,

Turbines

• A turbine consists of a circular disc to which a number of short blades are attached. Blades may be straight or curved

• The diameter of the turbine ranges from 30-50 % of the diameter of the vessel

• Turbines rotates at a lower speed than the propellers (50-200 rpm)

• Flat blade turbines produce radial and tangential flow but as the speed increases radial flow dominates. Pitched blade turbine produces axial flow

• Near the impeller zone of rapid currents, high turbulence and intense shear is observed

• Shear produced by turbines can be further enhanced using a diffuser ring (stationary perforated ring which surrounds the turbine)

• Diffuser ring increase the shear forces and liquid passes through the perforations reducing rotational swirling and vortexing

Advantages of Turbines

• Turbines give greater shearing forces than propellers though the pumping rate is less. Therefore suitable for

emulsification

• Effective for high viscous solutions with a wide range of viscosities.

• In low viscous materials of large volumes turbine create a strong currents which spread throughout the tank

destroying stagnant pockets

• They can handle slurries with 60 % solids

• Turbines are suitable for liquids of large volume and high viscosity, if the tank is baffled.

Vortex formation

• A strong circulatory flow pattern sometimes manifests into formation of a vortex near the impeller shaft.

Vortex can be formed when

• Shaft is placed symmetrically in the tank.

• Blades in the turbines are arranged perpendicular to the central shaft.

• At high impeller speeds

• In unbaffled tanks

Disadvantages of vortex formation

• Vortex formation reduces mixing intensity by reducing velocity of the impeller relative to the surrounding fluid

• When vortex reaches the impeller, air from the surface of the liquid are drawn and air bubbles are produced

• Air bubbles in the fluid can create uneven loading of the impeller blades

• Entrapped air causes oxidation of the substances in certain cases

• The tangential flow predominates when the shaft of the impeller is vertical & centrally located in the tank

• Vortex is created at the liquid surface when the liquid swirls around the vessel with little or no intermingling

As velocity is increased, the vortex is increased

Disadvantages of vortex

• Bad mixing due to swirling of the liquid layers

• Centrifugal force will throw the suspended particles towards the wall of tank then downward to the bottom

• Air is drawn into the mixed material which causes decomposition of oxidizable substances and foaming of others

Prevention of vortex formation

1. Impeller should be in any one of the position such as off central, inclined, side entering, etc., and should be deep in the liquid.

2. Baffled containers should be used. In such case impeller can be mounted vertically at the center.

3. Two or more impellers are mounted on the same shaft where greater depth is required

This system is known as push and pull mechanism

The bottom impeller is placed about one impeller diameter above the bottom of the tank It creates zone of high turbulence

4. Tank other than cylindrical in shape are used to prevent vortex formation. However, such shapes may facilitate the formation of dead spots

Suppression of vortex

• In small tanks The impeller is mounted off-center either vertically or tilted to destroy mixer symmetry & minimize tangential flow

• In large tanks Vertical baffles (perpendicular to tank walls) are installed on or just away the walls.. why?

To reduce tangential flow without affecting radial and axial flow

• In very large tanks The impeller is mounted in the side of the tank with shaft in horizontal plane

Homogenization

• Homogenization is defined as an intensive mixing of mutually insoluble phases to obtain a suspension or emulsion

• Pharmaceutical homogenizers are used to blend different kind of liquids uniformly, specially liquids having different properties

• Homogenizer actually reduces the size of particles of one material and dissolves it evenly throughout the other material

Factors influencing selection of an emulsifier

1. Quantity of emulsion to be prepared: Batch wise or continuous operation

2. Flow properties of liquids: Newtonian, plastic, pseudo plastic or dilatant

3. Temperature maintenance: Mixing will be effective at high temperatures provided the material is stable

4. Desired rate of cooling: If elevated temperatures are applied

Equipments

Rapisonic homogenizer

Colloidal mill

Silverson emulsifier

Silverson mixer -Emulsifier

Principle

• It produces intense shearing forces and turbulence by use of high speed rotors

• Circulation of material takes place through the head by the suction produced in the inlet at the bottom of the head

• Circulation of the material ensures rapid breakdown of the dispersed liquid into smaller globules

• It consists of long supporting columns and a central portion. Central portion consists of a shaft which is connected to motor at one end and other to the head

• Head carries turbine blades

• Blades are surrounded by a mesh, which is further enclosed by a cover having openings

Construction

It consists of a emulsifier head which is covered with the fine meshed stainless steel sieve

The emulsifier head consist of a number of blades which rotates at high speed in order to produce a powerful shearing action

The blades are rotated by using the electric motor fitted at the top.

WORKING

•The emulsifier head is placed in the vessel containing immiscible liquids, in such a way that it should get dipped into it

•When the motor is started, the liquids are sucked through the fine holed and the oil is reduced into the globules due to the the rotation of the blades

•The precision machined Silverson work head generates exceptionally high shear rates in a four stage

mixing/homogenizing process:

Stage 1

The high-speed rotation of the rotor blades within the precision machined mixing work head exerts a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the center of the workhead

Stage 2

Centrifugal force then drives the materials to the periphery of the workhead and subjects them to mechanical shear

Stage 3

This is followed by intense hydraulic shear and circulated back into the mix as the product is forced through the stator screen at high velocity.

Fresh material is continually drawn into the workhead, progressively reducing globule or particle size and quickly resulting in a homogeneous, uniform product

Stage 4

The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle

Uses

• Used for the preparation of emulsions and creams of fine particle size

Advantages

• Silver son mixer is available in different sizes to handle the liquids ranging from a few milli liters to several thousand liters

• Can be used for batch operations as well as for continuous operations by incorporating into a pipeline, through which the immiscible liquids flow

Disadvantages

• Occasionally, there is a chance of clogging of pores of the mesh

Colloid Mill

Principle

Colloidal mill works on the principle of rotor-stator

The size reduction is affected due to shearing, when the material is passed between the narrow gap of milling surfaces of rotor and stator.

A rotor turns at high speeds of 3000 – 20000rpm.

The high levels of hydraulic shear applied to the process liquid disrupt structures in the fluid.

Colloid mills are frequently used to increase the stability of suspensions, emulsions and can also be used to reduce the particle size of solids in suspensions

Higher shear rates leads to smaller droplets of 1 micron.

Based on a rotor rotating at high speed and very close to a conical stator, the particle size is done by modifying the gap between the rotor and the stator.

Construction

• A colloidal mill consist of a high speed rotor and a stator with a conical milling surfaces between

• Which is an adjustable clearance ranging from 0.002 to 0.03 inches

• The rotor speed is 3000 to 20000 rpm. The material to be ground should be pre milled as finely as possible to prevent damage to the colloidal mill

• Rotors and the stator may be smooth surfaced or rough surface. With the rotor and the stator there is a thin uniform film of material between them and it is subjected to the maximum amount of shear

Working

The material is placed into the mill though the inlet hopper. It is then passed through the narrow gap between the rotor and stator and thus reduced the fine particle size

A colloid mill is a hydraulic shear producing device

The colloid mill works to reduce the size of the suspended droplets. The mill allows the solid particles to become so small

The process of colloid milling is done through the addition of the heavier liquid into the chamber of the mill that performs the shearing process.

Once the heavier liquid has been added the lighter material whether it is a solid mass or a liquid of different viscosity is added to the material to start the mill.

When the milling portion of the function takes place, the materials are both stirred together within the mill at a high rate of speed

In other model the stator remains constant and the rotor will do the function of rotation.

It creates the amount of hydraulic shear needed to break down the materials

Advantages

• High throughput with excellent grinding result

• Infinitely adjustable gap settings between rotor/stator for control of particle size reduction

• Suitable for products of high viscosity range

• Capable of operation under pressures up to 16 bar

• High-value seal with wear-resistant materials

• High quality surface finishes for easy cleaning

• Other materials and finishes are available upon request

• Machine is self-draining

• Low noise levels

Disadvantages

• Requires high power for the running of the colloidal mill

• Using of wet materials

• Consumes more energy

Applications

Colloid mill is used for preparing suspensions, emulsions and ointments

Capable of producing pharmaceutical products with reduced particle size < 1 μ

Colloidal mill can be sterilized so it can be used in the production of sterile products

Ultrasonic Emulsifiers – Rapisonic homogenizer

Principle

• When a liquid is subjected to ultrasonic vibrations alternate regions of compression and rarefaction (reduction in the density) are produced in the liquid

• Cavities are formed in the regions of rarefaction which subsequently collapse in the regions of compression.

Which results great forces for emulsification

Construction

• It consists of a pump driven by a motor. It is connected to inlet tube and an out let tube.

• Head consists of a flat jet for liquid inlet. Facing the jet, a thin blade is present which vibrates at its natural frequency.

Advantages

• Can be used for batch process (by placing it in a tank) or for continuous process (by placing it in a pipeline)

• It can produce dispersed globules of one micron size

• As this method is highly efficient to decrease globule size, reduced concentration of emulgents is sufficient

• Its capacity of mixing liquids ranges from 20 – 500 liters per minute

• It is suitable for thermolabile substances since heat is not generated during mixing

Disadvantages

• It is useful only for low viscous liquids

For Mixing and Homogenization Detailed PDF Notes Click on Download Button

Also, Visit:

B. Pharma Notes | B. Pharma Notes | Study material Bachelor of Pharmacy pdf