High Performance Liquid Chromatography (HPLC)

HPLC – High Performance Liquid Chromatography

High Performance Liquid Chromatography, commonly known as HPLC, is a sophisticated analytical technique designed for the separation and analysis of complex mixtures. Unlike traditional liquid chromatography, HPLC utilizes high-pressure pumps to deliver the mobile phase, resulting in enhanced efficiency and resolution.

Difference between Column Chromatography and HPLC

|

Parameter |

Column chromatography |

HPLC |

|

Particle size – stationary phase |

60 – 200µ |

Small – 3-20µ |

|

Column size |

Large |

small |

|

Column material |

Glass |

Mostly metal |

|

Column packing pressure |

Low pressure |

High |

|

Sample load |

Low to medium(g/mg) |

Low to very low(µg) |

|

Column efficiency |

Low |

High |

|

Cost |

Low- hundreds |

High – lakhs |

|

Types of stationary phases used |

Limited range |

Wide range |

|

Mode of separation |

Preparative scale |

Analytical and preparative scale |

Types of HPLC Techniques

• Based on modes of chromatography

– Normal phase mode

– Reverse phase mode

• Based on principle of separation

– Adsorption chromatography

– Ion exchange chromatography

– Size exclusion (or) Gel permeation chromatography

– Chiral phase chromatography

• Based on elution technique

– Isocratic separation

– Gradient separation

• Based on the scale of operation

– Analytical HPLC

– Preparative HPLC

• Based on the type of analysis

– Qualitative analysis

– Quantitative analysis

HPLC Instrumentation

• Solvent Reservoir (HPLC solvent reservoir systems)

• Pumps

• Pre Guard Column

• Sample injection system

• Columns

• Detector

• Recorder and integrators

HPLC Solvent Reservoir systems

Pumps – Solvent Delivery system

• Mobile phase – pumped – column – high pressure – 1000 – 3000psi

• Column – particle size – 5- 10µ

Ideal characteristics of a Pump

• Non corrosive and compatible with solvent.

• Provide High pressure to push mobile phase

• Provide constant flow rate to mobile phase

• Should have reproducible flow rate

• Should not leak

• High pressure generated by pump should not lead to an explosion

• It should be easy to dismantle and repair

Types of Pumps

• Reciprocating pump

• Displacement pump

• Pneumatic pump

Reciprocating pump –

Constant flow rate

• Reciprocating piston – moves back and forth in hydraulic chamber

• By movement of piston – solvent flow into column under high pressure

• Piston moves backward – inlet valve open, exit valve closes – mobile phase drawn into the main chamber (cylinder)

• Piston moves to the front – inlet valve closes, exit valve opens

• Volume reduction in main chamber due to forward motion of piston – mobile phase moves out of the exit valve under high pressure

Advantages

• Generate high output pressure (upto10000 poise)

• Ready adaptability to gradient elusion

• Provide constant flow rate

• Pressure generated is so high that any back pressure generated in the column due to higher viscosity of stationary phase can be easily overcome

Disadvantage

• Pulsed flow – produce a base line noise on the chromatogram

Pulse dampner

• Dampen the pulses – wavy baseline caused – pumps

Mixing unit

• Mix – solvents – different proportions – column

Solvent degassing

Solvents – pumped with high pressure – gas bubbles – interfere – degassing

• Vacuum filtration – Not complete

• Helium purging – very effective – costly

• Ultrasonication – Ultrasonicator

Injector – Sample injection system

Septum injection port

• Syringe – inject the sample through a self-sealing inert rubber septum directly into the mobile phase

Stop flow septum less injection

• Flow of mobile phase through the column is stopped for a while

• Syringe is used to inject the sample

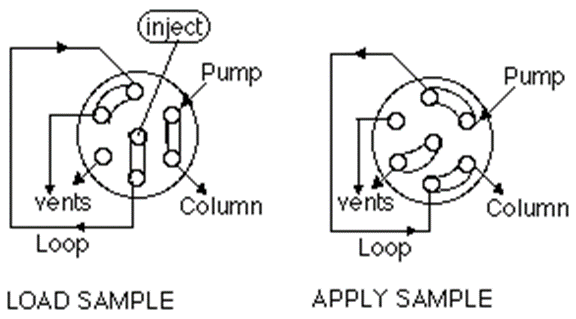

Rheodyne injector / loop valve type

• Sample introduced without causing interruption to mobile phase flow

• Volume of sample ranges between 2 µl to over 100 µl

Sample injection system

• Operation of sample loop

– Sampling mode

– Injection mode

• Sample is loaded into an external loop in the micro volume sampling valve – subsequently injected into the mobile phase by rotation of the valve

Column

Guard Column

• Small quantity of adsorbent

• Improves the life of the column

• Prefilter – Particles that clog the separation column,

• Compounds and ions that could ultimately cause baseline drift, decrease resolution, decrease sensitivity and create false peaks

• No separation

Column (Analytical)

Column material

• Stainless steel or heavy glass, polyethylene, PEEE (POLY ETHER ETHER KETONE)

• Colum length – 5 – 30cm

• Stationary phase – 25 µm or less

Standard column

• Internal diameter 4 – 5 mm & length 10 – 30 cm

• Size of stationary phase is 3 – 5 µm in diameter

• Used for the estimation of drugs, metabolites, pharmaceutical preparation and body fluids like plasma

Narrow bore column

• Internal diameter is 2 – 4 mm

• Require high pressure to propel mobile phase

• For high resolution analytical work -compounds with very high Rt

Short fast column

• Length 3 – 6 cm for substances which have good affinity towards the stationery phase

• Analysis time less (1- 4 min for gradient elusion & 15 – 120 sec for isocratic elusion)

Preparative column

• Used for analytical separation i.e. to isolate or purify sample in the range of 10-100 mg form complex mixture

– Length: 25 – 100 cm

– Internal diameter: 6 mm or more

Bonded Column

• C18 – Octa decyl silane column

• C8 – Octyl column

• C4 – Butyl

• CN – Nitrile

• NH2 – Amino column

Packing

• Depends on the mechanical strength of stationary phase

• Particle size of the stationary phase

– Particles of greater then 20 µm – dry packing

– Particles of lesser then 20 µm – slurry packing / wet packing

Dry packing

– Particle size greater than 20 µm filled into vertical clamped column in small quantity

– Deposition is done by tapping or vibrating the column

– Column is unclamped, tapped on the firm surface to obtain dense and reproducible packing

Wet/Slurry Packing

• Particle size with diameter less then 20 µm can only be placed wet as a suspension

• Suspension should be stable, should not sediment

Detectors

• Ultraviolet- visible detector

• Refractive index detector

• Flourimetric detector

Recorders and Integrators

• Recorders – to record the response obtained from the detector after amplification

• Record the baseline and all the peaks obtained, with respect to time

• Retention time for all the peaks can be calculated

• Integrators – improved versions of recorder with data processing capabilities

• They can record the individual peaks with retention time height and width of peak, peak area, etc

Applications

• Qualitative analysis

• Checking the purity

• Quantitative analysis

• Stability studies

Summary

• Principle of HPLC – partition

• Solvent Reservoir (HPLC solvent reservoir systems) – mixing unit – degassing of solvents

• Pumps – Pneumatic and reciprocating pumps are used

• Pre Guard Column acts as prefilter and made up of same material of column

• Sample injection system – Rheodyne injector, septum injection port

• Columns – Bonded column, packed columns and capillary columns are used

• Detector – Ultraviolet- visible, refractive index and Flourimetric detector

Frequently Asked Questions (FAQs)

- Is HPLC suitable for all types of compounds? HPLC is versatile and can handle a wide range of compounds, making it suitable for various applications in analytical chemistry.

- What are the common challenges faced in HPLC analysis? Common challenges include column degradation, baseline drift, and poor peak resolution. However, these challenges can be overcome with proper optimization and maintenance.

- How does HPLC compare to gas chromatography (GC)? HPLC and GC differ in principles and applications. While HPLC is suitable for a broader range of compounds, GC is often preferred for volatile substances.

- What role does HPLC play in pharmaceutical research? HPLC is integral to pharmaceutical research, aiding in drug development, quality control, and the analysis of complex pharmaceutical formulations.

- Can HPLC be used for environmental monitoring? Yes, HPLC is widely used in environmental monitoring for the analysis of pollutants, contaminants, and other substances in air, water, and soil.

Also, Visit:

B. Pharma Notes | B. Pharma Notes | Study material Bachelor of Pharmacy pdf

1 thought on “High Performance Liquid Chromatography (HPLC) – Principle, Instrumentation and Application”

Comments are closed.