Emulsion

Learning Objectives

At the end of this lecture, student will be able to

• Define emulsions

• Classify emulsions

• Discuss the identification tests for emulsions

• Explain the mechanism of action of Emulsifying agents

• Explain the parameters that influence stability of an emulsion

• Discuss the various theories of emulsification

• Explain the concepts of stability of emulsions

• Describe the methods of evaluation of emulsions

Emulsion

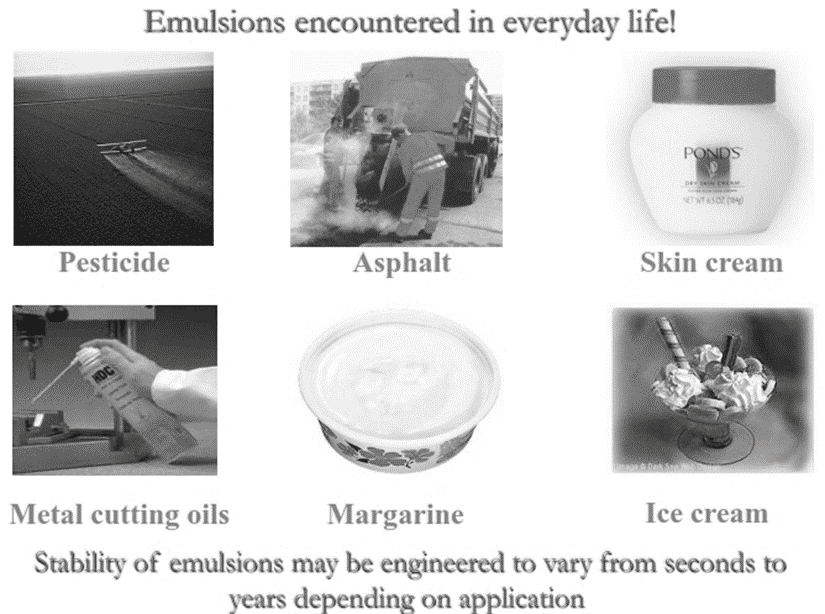

• An emulsion is a dispersion in which the dispersed phase is composed of small globules of a liquid distributed throughout a vehicle in which it is immiscible.

• In emulsion terminology, the dispersed phase is referred to as the internal phase, and the dispersion medium as the external or continuous phase.

• Emulsions having an oleaginous internal phase and an aqueous external phase are referred to as oil-in-water emulsions, and are commonly designated as “o/w”emulsions.

• Emulsions having an aqueous internal phase and an oleogenous external phase are referred to as water-in-oil emulsions, and are commonly designated as “w/o”emulsions.

• To prepare a stable emulsion, a third phase is necessary, that being an emulsifying agent.

Advantages of Emulsion

• Mask the unpleasant taste – Vitamin A

• Economical

• Improved bioavailability – Griseofulvin

• Sustained action of medicament multiple emulsions

• Diagnostic purposes – Radio opaque emulsions in X-ray examination

• Topical use – Cold cream, vanishing cream

Disadvantages of Emulsion

• Short shelf life – unstable

• Complete wastage in case of accidental breakage

Classification of emulsions

Based on dispersed phase

• Oil in Water (O/W): Oil droplets dispersed in water

• Water in Oil (W/O): Water droplets dispersed in oil

Based on size of liquid droplets

0.2 – 50 mm Macroemulsions (Kinetically Stable)

0.01 – 0.2 mm Microemulsions (Thermodynamically Stable)

Multiple Emulsions: O/W/O or W/O/W – Emulsion within a Emulsion – For sustained action

General Types of Pharmaceutical Emulsions

• Lotions

• Liniments

• Creams

• Ointments

• Vitamin drops

Emulsification

Emulsifying Agents

• It is a substance which stabilizes an emulsion.

• Pharmaceutically acceptable emulsifiers must also:

– be stable.

– be compatible with other ingredients.

– Be non – toxic.

– possess little odor, taste, or color.

– Not interfere with the stability of efficacy of the active agent.

Type Emulsifying Agents:

1) Carbohydrate Materials:

• Acacia, Tragacanth, Agar, Pectin. o/w emulsion.

2) Protein Substances:

• Gelatin, Egg yolk, Caesin o/w emulsion.

3) High Molecular Weight Alcohols:

• Stearyl Alcohol, Cetyl Alcohol, Glyceryl Mono stearate o/w emulsion, cholesterol w/o emulsion.

4) Wetting Agents:

• Anionic, Cationic, Nonionic

• o/w emulsion

• w/o emulsion

5) Finely divided solids:

• Bentonite, Magnesium Hydroxide, Aluminum Hydroxide o/w emulsion.

HLB and Use of Surfactants

Amphiphilic surfactants are characterized by the hydrophilic-lipophilic balance (HLB): a relative ratio of polar and non-polar groups in the surfactant

• HLB -1 to 3.5: Antifoams

• HLB – 3.5 to 8: Water-in-Oil Emulsifiers

• HLB – 7 to 9: Wetting and spreading agents

• HLB – 8 to 16: Oil-in-Water Emulsifiers

• HLB – 13 to 16: Detergents

• HLB -15 to 40: Solubilizers

Dispersion Process to Form Droplets

• Time of Agitation (1 – 5 min), after that the N of coalescence droplets = N of formed droplets.

• Intermittent shaking ( gives more droplets)

• Rapid & continuous shaking gives (hinder the breakdown of droplets)

• High speed Mixers, blinders & colloidal mills are recommended.

Tests for Emulsion Type (W/O or O/W emulsions)

1) Dilution Test:

• o/w emulsion can be diluted with water.

• w/o emulsion can be diluted with oil.

2) Conductivity Test:

• If continuous phase is water, emulsion conduct electricity and if oil is continuous phase it does not conduct electricity

3) Dye-Solubility Test:

• Water soluble dye will dissolve in the aqueous phase of O/W emulsion eg. Amaranth, Methylene blue

• Oil soluble dye will dissolve in the oil phase in W/O emulsion. Eg. Sudan III

4) Creaming test:

• W/O emulsion cream downwards as oil is less dense than water

• O/W emulsion cream upwards

Classifications & Mechanisms of Action of Emulsifying Agents

I. Classification in accordance with the Type of the film they form at the Interface between the two phases

II. In accordance to their chemical structure

Classification according to the type of the formed film

1. MONOMOLECULAR ADSORPTION AND FILM FORMATION

• Stabilize an emulsion by forming a monolayer of adsorbed molecules or ions at the O/W interface

• Film envelopes the droplets as they are formed

• Film should be compact and strong and should not break

• Even broken, should be flexible enough to be reformed

• For this even combinations of emulsifying agents are used to produce film of sufficient physical, chemical and mechanical properties

• Combination of surfactants should have both water soluble and oil soluble surfactants

• Hydrophilic surfactant approaches the interface from aqueous phase side

• Oil soluble surfactant approaches the interface from oily phase side

• At interface 2 surfactants interact to form complex and condense as monomolecular film

• But blend of surfactants may also produce poor quality emulsion sometimes if the interaction between them is not stronger at the interface Eg. Oleyl alcohol + sod. cetyl sulfate

• Surfactants reduces interfacial tension by which small droplets are formed which takes care of surface free energy changes during emulsification

• Small droplets combine with each other and form separate phases, which can be avoided by reducing interfacial tension

• Ionic surfactants impart charges on interfacial films. These films exert repulsive forces between 2 approaching globules and prevent their coalescence

2. MULTIMOLECULAR FILMS

• Hydrated lyophilic colloids form multimolecular films around droplets of dispersed oil.

• These hydrophilic colloids are adsorbed at the interface and prevent coalescence

• They do cause an appreciable ↓ in g.

• Their efficiency depends on their ability to form strong coherent multimolecular films.

• They are effective at higher concentration

• These act as a coating around the droplets & render them highly resistant to coalescence.

• They have affinity toward the oil phase and this facilitates interfacial adsorption

• Stability is improved by adding viscosity imparting agents like CMC, MC and tragacanth

3. SOLID PARTICLE FILMS

1st requirement: Small solid particles that are wetted to some degree by both aqueous & oily liquid phases act as emulsifying agents by forming film at the interface.

This film is a mechanical barrier and prevents coalescence

2nd requirement: The particles are small in relation to the droplets of the dispersed phase.

Eg. Bentonite, Veegum

Stability of emulsion depends on finer state of subdivision of solid particles, irregular surface and charge on the surface

Classification According to the Chemical Structure

• There is some correlation between this classification & that based on the mechanism of action.

• The majority of emulsifiers forming monomolecular films are synthetic, organic materials.

• Most of the emulsifiers that form multimolecular films are obtained from natural sources & are organic.

• A 3rd group (solid particles), invariably inorganic, that form films composed of finely divided solid particles.

• Accordingly, the classification, adopted divides e.a into synthetic, natural, & finely dispersed solids.

• A 4th group, the auxiliary materials are weak emulsifiers.

Synthetic Emulsifying Agents

• These are subdivided into: Anionic; Cationic & Non-ionic.

I. Anionics:

• The K, Na, & NH4 salts of lauric & oleic acids are soluble in water & are good O/W e.a.:

• They have a disagreeable taste & are irritating to the GI tract.

• Solutions of alkali soaps

• Sulfated alcohols (neutralized sulfuric acid esters of such fatty alcohols) as lauryl & cetyl alcohol:

2. Cationics

• e.g. is Cetyltrimethyl-ammonium bromide

• CH3(CH2)14(CH2)N+(CH2)3Br –

• This makes them desirable in emulsified anti-infective products such as skin lotions & creams. Stabilizing or auxiliary e.a. such as cetostearyl alcohol is used.

3. Non-ionics

They are not susceptible to pH changes & the presence of electrolytes. The most frequently used are the:

1. glyceryl esters,

2. polyoxyethylene glycol esters & ethers,

3. sorbitan fatty acid esters & their polyoxyethylene derivatives,

4. polyoxy ethylene / polyoxypropylene block copolymers.

Natural Emulsifying Agents

1. Acacia is a carbohydrate gum that is soluble in water & forms O/W emulsions.

• Emulsions prepared with acacia are stable over a wide pH range.

• It is necessary to preserve acacia emulsions against microbial attack.

2. Gelatin, a protein, has been used for many years as an emulsifying agent.

• It can have 2 iso-electric points, depending on the method of preparation.

• Type A gelatin, (acid treated precursor), [iso-electric point ≈ pH 7 & 9].

• Type A acts around pH 3, where it is +ly charged.

• Type B gelatin, (alkali treated precursor), [isoelectric point ≈ pH 5].

• Type B gelatin is best used around pH 8, where it is -ly charged.

• Gums such as tragacanth, acacia, or agar that are -ly charged are to be used with gelatin, then Type B material should be used at an alkaline pH.

• Lecithin obtained from both plant (eg, soybean) & animal (eg, egg yolk) sources.

• The primary component of most lecithins is phosphatidylcholine. Frequently, lecithins that are used as emulsifiers also contain mixtures of phosphatides, including:

1. Phosphatidylserine

2. Phosphatidylinositol

3. Phosphatidylethanolamine

4. Phosphatidic acid

Finely Dispersed Solids

• They form particulate films around the dispersed droplets, producing emulsions that are coarse & have considerable physical stability.

• The group of compounds used most frequently are the colloidal Bentonites.

• Depending on the sequence of mixing it is possible to prepare both O/W & W/O emulsions.

• When an O/W emulsion is desired, the bentonite is first mixed in water & allowed to hydrate so as to form a magma. The oil phase is then added gradually with constant titration

• To prepare a W/0 emulsion, the bentonite first dispersed in oil, the water is then added gradually,

• Veegum is also used as a solid particle emulsifying agent it is employed most extensively as a stabilizer in cosmetic lotions & creams.

• Concentrations of less than 1% Veegum will stabilize an emulsion containing anionic or nonionic emulsifying agents.

Auxiliary Emulsifying Agents

• They include those compounds that are normally unable themselves of forming stable emulsions.

• Their main use lies in their ability to function as thickening agents and thereby help stabilize the emulsion.

Inversion of Emulsions (Phase inversion)

• O/Wà W/O and W/O àO/W emulsion

1. The order of addition of the phases

• W à O + emulsifier à W/O

• O à W + emulsifier à O/W

2. Nature of emulsifier

• Making the emulsifier more oil soluble tends to produce a W/O emulsion and O/W emulsion.

3. Phase volume ratio

• Oil/Water ratio á à W/O emulsion

• Oil/Water ratio â àO/W emulsion

4. Temperature of the system

• á Temperature of O/W makes the emulsifier more hydrophobic and the emulsion may invert to W/O.

5. Addition of electrolytes and other additives.

• Strong electrolytes to O/W (stabilized by ionic surfactants) may invert to W/O

Example. Inversion of O/W emulsion (stabilized by sodium cetyl sulfate and cholesterol) to a W/O type upon addition of polyvalent Cation

Physical Instability of Emulsions

Breaking

• Separation of the internal phase from the external phase is called Breaking of the emulsion. This is irreversible.

• Protective sheath around the globule destroys

• Protect emulsions against the extremes of cold and heat.

• Emulsions may be adversely affected by microbial contamination.

Flocculation

• Globules aggregate and form colonies at the external phase which leads to instability

• Flocculation depends on

a) Globule size distribution

b) Charge on the globule surface

c) Viscosity of the external medium

• Uniform sized globules prevent flocculation. This can be achieved by size reduction

• Charge on globules exert repulsive forces with adjacent globules – Using electrolytes, non-ionic EA

• Viscosity of medium increased, due to which floccules becomes immobile – Using viscosity improving agents Eg. Hydrocolloids

• Flocs move either upward or downward leading to Creaming

• Flocculation is due to interaction of attractive and repulsive forces

Creaming

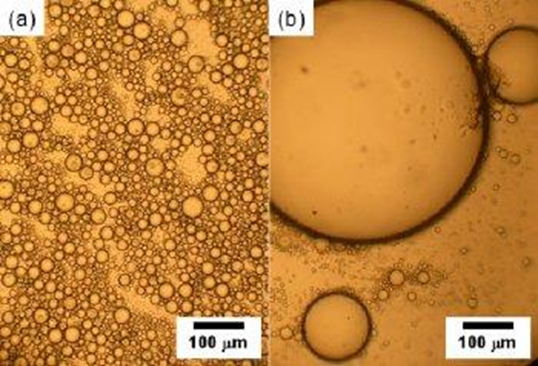

• Creaming is concentration of globules at top or bottom of emulsion – Reversible process

• Creaming is due to density difference between the dispersion medium and dispersed phase

• Observed due to movement of individual globules or difference in color shade of the layers

• When dispersed phase is less dense than dispersion medium – upward creaming

• When dispersed phase is denser than dispersion medium – downward creaming

• Cream can be redispersed by agitation

• In creaming drug is not uniformly distributed, leading to variable dosage

• Creaming is influenced by Globule size, Viscosity and Density difference

• Can be rectified by adjusting viscosity imparting agents using tragacanth, methyl cellulose etc

• Reducing particle size by homogenization

Coalescence

• Globules fuse with each other and form bigger globules

• The film around the droplet destroys due to which globule size increases and number decreases

• Coalescence is due to

a) Insufficient amount of EA

b) Alerted partitioning of EA

c) Incompatibilities between EA

Theories of Emulsification:

Surface Tension Theory:

• lowering of interfacial tension.

Oriented-Wedge Theory:

• Mono molecular layers of emulsifying agents are curved around a droplet of the internal phase of the emulsion.

Interfacial film theory:

• A film of emulsifying agent prevents the contact and coslescing of the dispersed phase.

Viscosity theory:

Modern theory of emulsification:

1) The surface-tension theory

• According to the surface-tension theory of emulsification, the use of surfactants as emulsifiers and stabilizers results in the

• Lowering of the Interfacial tension of the two immiscible liquids,

• Reducing the repellent force between the liquids

• Diminishing each liquid’s attraction for its own molecules.

• The surfactants facilitate the breaking up of large globules into smaller ones, which then have a lesser than usual tendency to reunite or coalesce.

2) The oriented-wedge theory

• The oriented-wedge theory assumes monomolecular layers of emulsifying agent curved around a droplet of the internal phase of the emulsion.

• The theory is based on the presumption that certain emulsifying agents orient themselves about and within a liquid in a manner reflective of their solubility in that particular liquid.

3) The plastic- or interfacial-film theory

• The plastic- or interfacial-film theory places the emulsifying agent at the interface between the oil and water, surrounding the droplets of the internal phase as a thin layer of film adsorbed on the surface of the drops.

• The film prevents the contact and coalescing of the dispersed phase; the tougher and more pliable the film, the greater the stability of the emulsion.

4) Viscosity theory

• Increase in viscosity will increase stability. But this fails to explain the stability of milk whose viscosity is less.

5) Modern theory

• This explains why emulsions are thermodynamically unstable

• When a liquid is mixed with another liquid one will disperse as fine droplets in another – 5mins –size is based on agitation and time – but it is unstable because of more cohesive force than attractive forces.

So to prepare a stable emulsion

• Dispersion of one liquid as droplets throughout the other – increases free energy

• Combining these droplets to reform initial bulk liquid – decreases free energy

• The process is spontaneous – net effect is zero.

• It is necessary to increase first step and decrease second step, due to which emulsion can be stabilised

• Emulsifying agents helps in this process

• It acts by the following phenomenon

• Adsorbed at oil/water interface to form monomolecular film

• Adsorbed at oil/water interface to form multimolecular film

• Adsorbed at oil/water interface to form particulate film

Stability of Emulsions

• An emulsion is considered to be physically unstable if

(a) Internal or dispersed phase upon standing tends to form aggregates of globules,

(b) Large globules or aggregates of globules rise to the top or fall to the bottom of the emulsion to form a concentrated layer of the internal phase,

c) If all or part of the liquid of the internal phase separates and forms a distinct layer on the top or bottom of the emulsion as a result of the coalescing of the globules of the internal phase.

Factors improving physical stability of emulsions

a) Physical nature of the interfacial surfactant film

• For mechanical stability, surfactant films are characterized by strong lateral intermolecular forces and high elasticity

• On moderate shaking emulsion should be redispersible

• Films should be tough to prevent coalescence

• Physical properties of the film depends on pH

• Suitable EA should be added to achieve the desired film property

(b) Charge of electrical double layer

• When Ionic emulsifier is used electrical double layer possesses charge

• Repulsive forces due to like charges on the surface of the globules prevent the aggregation of globules

• Charge also depends on pH

(c) Viscosity of the continuous phase

• Emulsion are more stable in concentrated form than when diluted

• So viscosity should be increased by adding natural or synthetic thickening agents

(d) Size distribution of droplets

• Emulsion with a fairly uniform size distribution is more stable

• But this is difficult to achieve due to viscosity, phase volume ration and density difference

(e) Phase volume ratio

• As volume of dispersed phase á stability of emulsion â and vice versa (eventually phase inversion can occur)

(f) Temperature

• Temperatureá, usually emulsion stability â

• Temp affects – Interfacial tension, solubility of surfactant, and viscosity of liquid, phases of interfacial film.

(g) Particle Size

• As globule size decreases, they exhibit Brownian motion

• Diameter of globule is responsible for creaming of emulsions

• Optimum globule size for maximum stability

(h) Phase Density

• Difficult to adjust the density of the phases

• To some extent oil phase density can be enhanced by adding brominated oil, when oil is an external phase

(i) Poor Experimental Techniques

• Process conditions – sequencing steps, method of addition, and growth of microorganisms

Evaluation of Emulsions

Phase separation – volume of separated phase due to Creaming and Coalescence after suitable time intervals

Micromertic property –Particle size, globule size, Globule size distribution

Electrokinetic property – Zeta potential measurement by Electrophoresis

Rheology – Viscosity determination by Brookefield’s Viscometer at varying RPM

Centrifugation – at 5000rpm for 5 minutes

Freeze Thaw Cycling – Successive heating and cooling cycles (0 to 400C)

Accelerated Stability Testing – ICH guidelines – 45±20C with 75±5%RH – 6 months

Microwave Irradiation – for stability – when exposed to microwave irradiation, surface temp. of emulsion should be highest and temp between surface and bottom should be small for most stable emulsion

Preservation of Emulsions

• Selection of preservatives for emulsion is based on Type of emulsion, Volume fraction of aqueous phase, pH, Formulation ingredients, Container, Aeration and Therapeutic value

Summary

• An emulsion is a dispersion in which the dispersed phase is composed of small globules of a liquid distributed throughout a vehicle in which it is immiscible.

• Based on dispersed phase emulsions are classified as Oil in Water (O/W): Oil droplets dispersed in water, Water in Oil (W/O): Water droplets dispersed in oil, Macro emulsions and Micro emulsions

• Emulsifiers must be stable, be compatible with other ingredients, non – toxic, possess little odor , taste , or color and does not interfere with the stability of efficacy of the active agent

• Emulsifiers acts in accordance with the type of the film they form at the Interface between the two phases and in accordance to their chemical structure

• Hydrated lyophilic colloids form multimolecular films around droplets of dispersed oil.

• These hydrophilic colloids are adsorbed at the interface

• Most of the emulsifiers that form multimolecular films are obtained from natural sources & are organic.

• Accordingly, the classification, adopted divides e.a into synthetic, natural, & finely dispersed solids.

• Auxillary emulsifying agents include those compounds that are normally unable themselves of forming stable emulsions.

• They are used as thickening agents and thereby help stabilize the emulsion

• Surface Tension Theory: lowering of interfacial tension.

• Oriented-Wedge Theory: mono molecular layers of emulsifying agents are curved around a droplet of the internal phase of the emulsion.

• Interfacial film theory: A film of emulsifying agent prevents the contact and coslescing of the dispersed phase.

• Viscosity theory:

– Modern theory of emulsification

• Emulsions are Kinetically Stable

• An emulsion is considered to be physically unstable if the internal or dispersed phase upon standing tends to form aggregates of globules

• Evaluation of Emulsions include Phase separation, Micromertic property, Electrokinetic property, Viscosity, Centrifugation, Freeze thaw cycling and Accelerated stability testing

Also, Visit: Biotechnology Notes