Packaging Materials in Pharmaceutical Industry

Packaging Materials in Pharmaceutical Industry

- Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use.

- Packaging also refers to the process of design, evaluation, and production of packages.

- Pharmaceutical packaging can be defined as the economical means of providing presentation, protection, identification, information, convenience, compliance, integrity and stability of the product.

Types of Packaging

- Primary packaging- is the material that first envelops the product and holds it. This is usually the smallest unit of distribution or use. Ex. Aerosol spray can, blister packs, bottles

• Secondary packaging – the package external to primary package is known as secondary package, this package provides additional protection during warehousing and also provides information about drug product ex. Boxes, cartons, leaflets

• Tertiary packaging – It is outer package of secondary packaging & prevents damage to the products. It is used for bulk handling & shipping.

Characteristics of Packaging Material

• The material selected must have the following characteristics

• Must meet tamper-resistance requirements

• Must be FDA approved

• Must be non-toxic

• Must not impart odor/taste to the product

• Must not reactive with the product

• They must protect the preparation from environmental conditions

Types of Packaging Materials Used For Pharmaceutical Packaging

GLASS

• Glass has been widely used as a drug packaging material.

• Glass is composed of sand, soda ash, limestone, & cullet.

• Si, Al, Na, K, Ca, Mg, Zn & Ba are generally used into preparation of glass.

Advantages

• They are hygienic and suitable for sterilization

• They are relatively non-reactive ( depending on the grade chosen)

• It can accept a variety of closures

• They can be used on high speed packaging lines

• They are transparent.

• They have good protection power.

• They can be easily labeled.

DISADVANTAGES

• It is relatively heavy

• Glass is fragile so easily broken.

• Release alkali to aqueous preparation

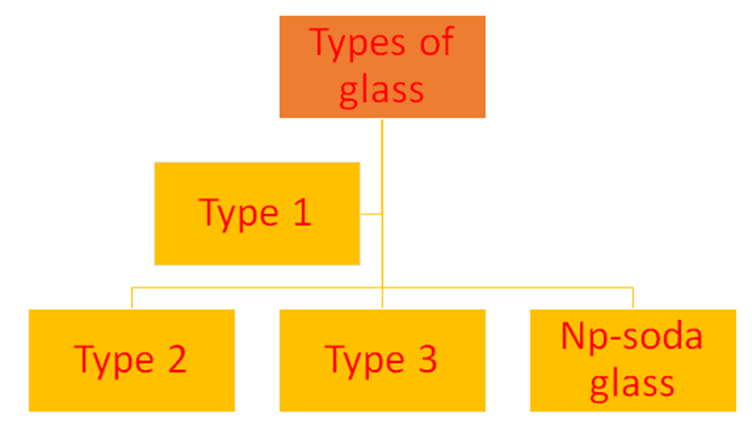

Type of Glass

• Type I—Highly resistant borosilicate glass

• Type II—Treated soda lime glass

• Type III—soda lime glass

• NP—soda glass (non parenteral usage)

Plastic

• Plastics may be defined as any group of substances, of natural or synthetic origins, consisting chiefly of polymers of high molecular weight that can be moulded into a shape or form by heat and pressure.

Advantages

• Less weight than glass,

• flexible

• Variety of sizes and shapes

• Essentially chemically inert, strong, rigid Safety use, high quality, various designs

• Extremely resistant to breakage

Disadvantages

• Absorption permeable to moisture

• Poor printing, thermostatic charge

Types of plastic

Thermosetting

• When heated they may become flexible but they do not become liquid

• e.g. Urea-formaldehyde (UF), Phenol formaldehyde, Melamine formaldehyde (MF), Epoxy resins (epoxides), Polyurethanes (PURs)

Thermoplastics

• On heating they are softened to a viscous fluid which hardens again on cooling.

• 2. e.g. Polyethylene{HDPE – LDPE}, Polyvinylchloride(PVC),Polystyrene Polypropylene, Nylon(PA), Polyethylene terephthalate(PET) ,Polyvinylidene chloride(PVdC), Polycarbonate Acrylonitrile butadiene styrene(ABS)

METALS

• Metals are used for the construction of containers. The metals commonly used for this purpose are aluminum, tin plated steel, stainless steel, tin, and lead

Advantages

• They are impermeable to light, moisture and gases.

• They are made into rigid unbreakable containers by impact extrusion.

• They are light in weight compared to glass containers.

• Labels can printed directly on to their surface

Disadvantages

• They are expensive

• They react with certain chemicals

Types of Metals

• Tin containers are preferred for food, pharmaceuticals and any product for which purity is considered.

• Tin is the most chemically inert of all collapsible metal tubes

• Lead has the lowest cost of all tube metals and is widely used for non-food products such as adhesives, inks. paints and lubricants.

• Lead should never be used alone for anything taken internally because of the risk lead poison

• With internal linings, lead tubes are used for products such as chloride tooth paste.

• Aluminium tubes offer significant savings in product shipping costs because of their light weight

• They are attractive in nature

RUBBER

• Rubber is used mainly for the construction of closure meant for vials, transfusion fluid bottles, dropping bottles and as washers in many other types of product

Types of Rubber

BUTYL RUBBER

Advantages:

• Permeability to water vapour .Water absorption is very low. They are relatively cheaper compared to other synthetic rubbers

Disadvantages:

• Slow decomposition takes place above 130 Degree C. Oil and solvent resistance is not very good

NITRILE RUBBER

Advantages:

• Oil resistant due to polar nitrile group. Heat resistant.

Disadvantages:

• Absorption of bactericide and leaching of extractives are considerable.

CHLOROPRENE RUBBERS

Advantages:

• Oil resistant. heat stability is good.

SILICON RUBBERS

Advantages:

• Heat resistance.Extremely low absorption and permeability of water. Excellent aging characteristic

Paper

• Paper and paper boards as packaging material are used to prepare containers as envelops for dispensing powders, a few tablets few capsules, etc. of as cartoons boxes and drums for storing large quantities of drugs in an industry.

• They are mostly used for secondary packaging and tertiary packaging