Fermentation process of Glutamic acid

Fermentation process of Glutamic acid

Session Objectives

At the end of the session, student will be able to

• Explain the fermentation process of Glutamic acid

History of Glutamic acid

• The history of the first amino acid production dates back to 1908 when Dr. K. Ikeda, a chemist in Japan, isolated glutamic acid from kelp, a marine alga, after acid hydrolysis and fractionation.

• He also discovered that glutamic acid, after neutralization with castic soda, developed an entirely new, delicious taste.

• This was the birth of the use of monosodium glutamate (MSG) as a flavour-enhancing compound.

• The breakthrough in the production of MSG was the isolation of a specific soil-inhabiting gram-positive bacterium, Corynebacterium glutamicum, by Dr. S. Ukada and Dr. S. Kinoshita in 1957.

• The successful commercialization of monosodium glutamate (MSG) with this bacterium provided a big boost for amino acid production and later with other bacteria like E. coli as well.

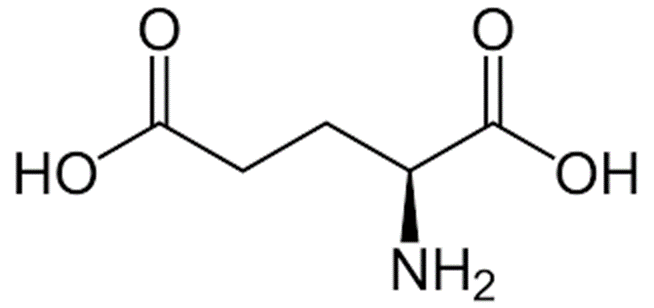

Glutamic acid

• It is an α-amino acid that is used by almost all living beings in the biosynthesis of proteins.

• It is non-essential in humans, meaning the body can synthesize it. It is also an excitatory neurotransmitter, in fact the most abundant one, in the vertebrate nervous system.

• It serves as the precursor for the synthesis of the inhibitory gamma-aminobutyric acid (GABA) in GABA-ergic neurons.

Uses of Glutamic acid

• It helps the nerve cells in the brain to send and receive information from other cells.

• It may be involved in learning and memory.

• Glutamic acid is widely used in the production of monosodium glutamate (MSG) which is commonly known as the ‘seasoning salt’.

• Monosodium glutamate is condiment and flavour-enhancing agent

• In hair loss and as anti-ageing agent

Production of Glutamic acid

• Glutamic acid commercial production by microbial fermentation provides 90% of world’s total demand, and remaining 10% is met through chemical methods.

• Organism – Corynebacterium glutamicum

• Fermentors as large as 500 m3

• Media composition – carbohydrate (glucose, molasses, sucrose, etc.), peptone, inorganic salts and biotin.

• Biotin concentration in the fermentation medium has a significant influence on the yield of glutamic acid

• Duration – 2-4 days

• The broth contains glutamic acid in the form of its ammonium salt.

Recovery

• The bacterial cells are separated and the broth is passed through a basic anion exchange resin.

• Glutamic acid anions get bound to the resin and ammonia is released.

• This ammonia can be recovered via distillation and reused in the fermentation.

• Elution is performed with NaOH to directly form monosodium glutamate (MSG) in the solution and to regenerate the basic anion exchanger.

• From the elute, MSG may be crystallized directly followed by further conditioning steps like decolourization and serving to yield a food-grade quality of MSG.

• α-ketoglutaric acid serves as the precursor of glutamic acid and the conversion of the α- ketoglutaric acid to glutamic acid occurs in presence of enzyme glutamic acid dehydrogenase.

• It has been found that if penicillin is added in the medium, the glutamic acid production can be increased manifold.

FAQs

- Is glutamic acid the same as monosodium glutamate (MSG)? No, glutamic acid is an amino acid, while monosodium glutamate is a sodium salt of glutamic acid commonly used as a flavor enhancer.

- Are there natural sources of glutamic acid? Yes, glutamic acid is naturally found in various foods, such as tomatoes, cheese, and soybeans.

- Does glutamic acid only enhance savory flavors? While glutamic acid is known for enhancing savory flavors, it can also contribute to overall taste enhancement.

- Is monosodium glutamate (MSG) safe to consume? Yes, extensive scientific research suggests that moderate consumption of MSG is safe for the majority of people.

- Can glutamic acid be produced without fermentation? While fermentation is a common method, researchers are exploring alternative ways to produce glutamic acid sustainably.

Also, Visit: Biotechnology Notes