Fermentation Process of Griseofulvin

Fermentation process of Griseofulvin

Session Objectives

At the end of the session, the student will be able to

• Explain the fermentation process of Griseofulvin

Griseofulvin

• Griseofulvin is an antifungal antibiotic first isolated from a Penicillium species in 1939.

• It is a secondary metabolite produce by the fungus Penicillium griseofulvum.

• The compound is insoluble in water

• Slightly soluble in ethanol, methanol, acetone, benzene, CHCl3, ethyl acetate, and acetic acid.

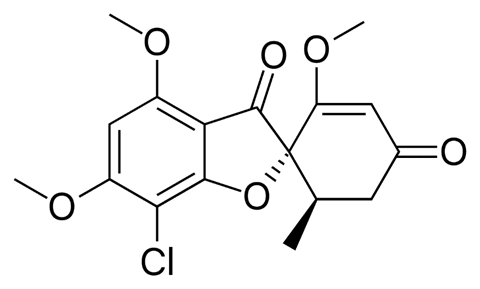

• Molecular formula – C17H17ClO6

Mechanism of Action of Griseofulvin

• Griseofulvin inhibit fungal cell mitosis and nuclear acid synthesis.

• It also binds to and interferes with the function of spindle and cytoplasmic microtubules by binding to alpha and beta tubulin.

• It binds to keratin in human cells, and then once it reaches the fungal site of action, it binds to fungal microtubules thus altering the fungal process of mitosis.

Uses of Griseofulvin

• It is used in the treatment of Ringworm of the Beard

• Ringworm of Scalp

• Fungal Disease of the Nails

• Ringworm of Groin Area, Athlete’s Foot

• Ringworm of the Body.

Fermentation Process of Griseofulvin

• Organisms used – Penicillium griseofulvum

Media composition – Czapek Dox Medium

– Glucose 5%

– Sodium Nitrate 0.2%

-Potassium Hydrogen Phosphate 0.1%

-Magnesium Sulphate 7H20 0.05%

• The pH of Czapek-Dox medium was adjusted between 6.0 – 7.2.

• The medium was dispensed in the fermenter

• The fresh sample of mycelial suspension of fungus Peccillium griseofulvum from the fresh slope on raper steep agar (Czapek-Dox medium + corn steep+ agar) was obtained.

• The solution was autoclaved for 200 minutes at 120°C at 15lbs pressure and fermented for 14 days at 24°C.

Pretreatment of Broth

• The broth is heated above 60°C for 20- 30minutes.

• After heating, sufficient coagulation of material occurs to produce a valuable improvement in separation characteristics of the broth.

• The period of heating may be short, 5-10 minutes at 80°C having been found to provide a satisfactory increase in filtration rate.

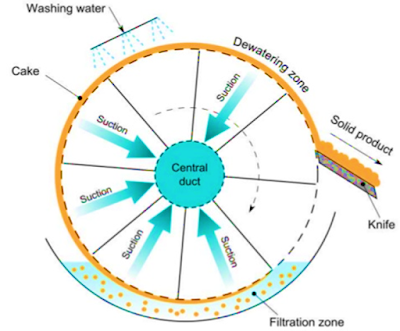

Filtration

• Drum covered with diatomaceous earth matter and allowed to rotate under vacuum with half immersed in the slurry tank.

• Small amount of coagulation agent added to broth and pumped into the slurry tank.

• As drum rotates in the slurry tank under vacuum thin layer of coagulated particles adhere to drum

• The layer thickens to from cake.

• As the cake portion in the drum comes to the upper region which is not immersed in the liquid it is washed with water and dewatered immediately by blowing air over it.

• Then before the dried portion is again immersed into the liquid it is cut off from drum by knife.

Extraction

• Griseofulvin is extracted in the cold acetone

• The extractions with the cold acetone may be carried out with efficiencies between 75-96% or even up to 99.5%.

• The volume of acetone should be 3-5 times the mycelial felt.

Decolorization

• The color of the extract can be improved by the addition of calcium hydroxide usually 2.5-50 g/liter preferably 5- 30 g/liter.

• The pH of the extract should be above 10. It can be neutralized by the removal of lime or by using mineral acid.

Isolation and separation

• The impurities or waxy substances are removed by washing it with a solvent in which griseofulvin is insoluble.

• Hydrocarbon solvents, generally aliphatic hydrocarbons such as hexane or petroleum containing a high portion of hexane are in general suitable for this step.

Precipitation and Purification

• Griseofulvin can be precipitated from the solvent extract in various ways.

• One of the method is using the liquid solvent in which griseofulvin is substantially insoluble.

• Griseofulvin non-solvent is preferably water.

• The alkaline water is more effective for the removal of colored impurities present in the crystals of the griseofulvin.

• Water is made alkaline with ammonia or an alkali metal carbonate or alkali metal hydroxide.

• The suitable pH is about 8.5.

• The suitable washing media are dry or wet acetone, a lower alkanol for example methanol or butanol.

• Marked purification is obtained with the use of methanol for this step.

Also, Visit: Biotechnology Notes