Conical Disc Centrifuge / De laval Clarifier

Conical Disc Centrifuge

As it is clarified, solids or immiscible liquids are present in low concentration in the feed complete clarification of the feed is possible by centrifugal means

Principle

• It is a sedimentation centrifuge

• The separation is based on the difference in the densities between the phases under the influence of centrifugal force

• In this, a number of cone-shaped plates are attached to a central shaft (which has the provision for feed) at different elevations

• During centrifugation, the dense solids are thrown outwards to the underside of the cone-shaped casing, while the lighter clarified liquid passes over the bowl and recovered from the top of the cone

Construction

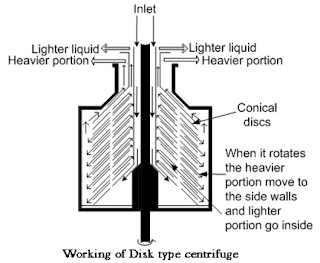

• The construction of a conical disc centrifuge is shown in the figure

• It construction of a shallow form of bowl contacting a series of conical discs are made up of a thin sheet of metal or plastic separated by narrow spaces

• Matching hole in the disc (above halfway between the axis and the wall of the bowl) from the channel through which the liquid passes

• A concentric tube is placed surrounding the central drive shaft

Working

• Centrifuge is allowed to rotate.

• Low speed and short time of centrifugation is sufficient to give high degree of clarification

• The feed is introduced through the concentric tube surrounding the shafts

• The feed flow down and enters in to the space between the discs (show by the narrows)

• During centrifugation, the liquid flow in to the channel (holes at the centre of disc) and upward past the discs

• These substances move along the surfaces of the discs to the limits of the inner and outer layers

• The solids and heavy liquids are thrown outward and move underside of the discs

• Then the solids deposit at the bottom of the cone, which is removed intermittently

• The lighter liquid moves to the upper side of the discs

• The liquid rises to the top and escapes from the outlet

Uses

• Two immiscible liquids can be easily separated by a continuous process after liquid/liquid extraction as in the case of the manufacture of antibiotics

• Suspensions containing low concentrations of solids can be separated quickly. Solids that are gelatinous are slimy can be separated by disc cone centrifuge. Such substances may plug the filter in the other methods

• Starch is collected after washing and purification stages

• In the manufacture of insulin, the liquor is clarified to remove the precipitated proteins

• Concentration of one fluid phase is possible as in the separation of cream from milk, the concentration of rubber latex, removing solids from lubricating oils, inks, and beverages

Advantages

• Conical disk centrifuges are compact occupying a minimal space

• The separating efficiency is very high, so the particles are deposited very rapidly. It is suitable if the sediment is a fluid deposit or sludge

• By controlling the speed of rotation and rate of flow, particles are separated into size fractions

Disadvantages

• The construction of a conical disc centrifuge is complicated

• Its capacity is limited

• It is not suitable if the sediment of solid forms a hard cake

FAQs

- Is the Conical Disc Centrifuge suitable for all types of liquids?

- The Conical Disc Centrifuge is versatile and can handle a wide range of liquids, but it’s essential to consider specific characteristics for optimal performance.

- How often should the Conical Disc Centrifuge undergo maintenance?

- Regular maintenance is key. Depending on usage, a schedule for inspections and lubrication should be established to prevent issues.

- What makes the De Laval Clarifier different from other centrifuge types?

- The De Laval Clarifier distinguishes itself with its conical disc design, enhancing separation efficiency compared to other centrifuge technologies.

- Can the Conical Disc Centrifuge be retrofitted into existing industrial processes?

- Yes, in many cases, the Conical Disc Centrifuge can be retrofitted, but a thorough evaluation is recommended to ensure compatibility.

- Are there any environmental benefits to using the Conical Disc Centrifuge?

- Yes, the Conical Disc Centrifuge’s efficiency contributes to reduced waste and energy consumption, aligning with sustainable practices.

B. Pharma Notes | B. Pharma Notes | Study material Bachelor of Pharmacy pdf