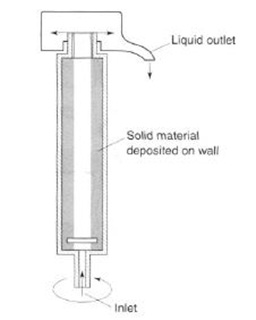

Tubular-bowl centrifuges (centrifugal sedimenters)

Used to separate solids and liquids

when the solid content is low. These consist of a cylindrical ‘bowl’

Around 100 mm in diameter and 1 m

long, which rotates at 300-1000 s-1

The product enters at the bottom

and centrifugal force causes solids to be deposited on the wall as it passes up

the bowl

The liquid overflows from the top

This type of centrifuge can also be

used to separate immiscible liquids

Rate of sediment can be control by

controlling the inlet rate

The uses of centrifugal sedimenters

include liquid/liquid separation

E.g. During antibiotic manufacture

and purification of fish oils, the removal of very small particles, the removal

of solids that are Compressible and which easily block the filter medium

The separation of blood plasma from

whole blood (need C =3000)

The separation of different

particle size fractions, and examining the stability of emulsions

Principle

• Super centrifuge is a

sedimentation centrifuge

• The separation is based on the

difference in the densities between two immiscible liquids

• Centrifugation is done in the

bowl of small centrifuge

• During centrifugation, the

heavier liquid is thrown against the wall, while the lighter liquid remains as an

inner layer

• The two layers are simultaneously

separated using modified weirs

Construction

• It consists of a long hallow

cylindrical bowl of small diameter

• It is suspended from a flexible

spindle at the top and guided at the bottom by loose-fit bushing

• It can be rotated on its

longitudinal axis

• Provision is made at the bottom

for the feed inlet using pressure system

• The liquid outlets are provided

at different heights at the top of the bowl, and modified weirs, are attached